----------------------------------------------------------------------- Page 15

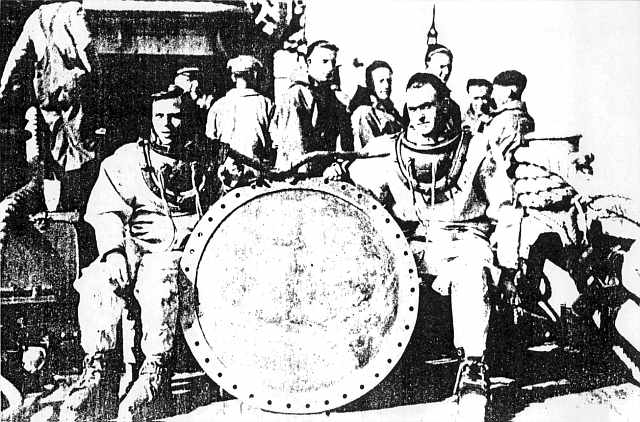

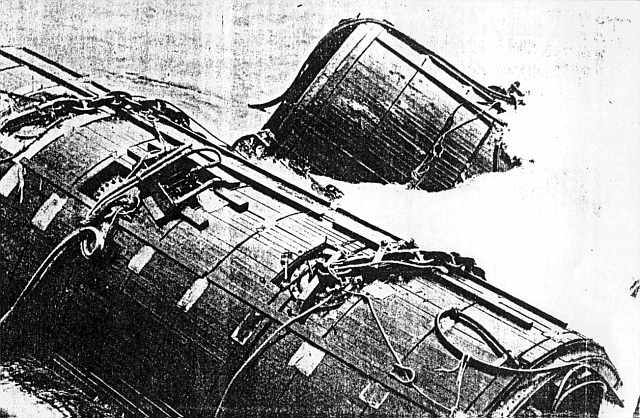

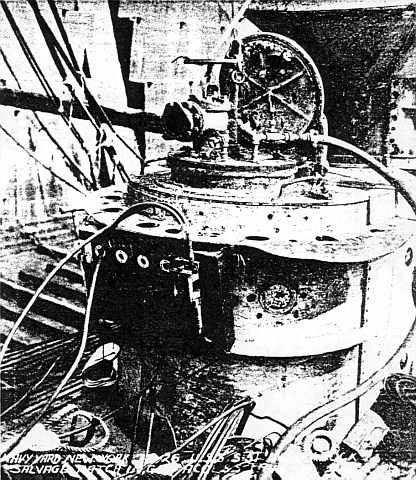

Figure 5: Main induction valve bonnet.

(Note 1-inch steel pipe which jammed under valve disk.)

----------------------------------------------------------------------- Page 16

Work on the first tunnel, at frame 46, was started on October 22. The divers

available had all done most of their diving in chasing lost torpedoes and were

consequently experienced in using a washing hose for digging out buried

torpedoes. Tunneling was therefore the thing they knew most about, and no

special difficulty was anticipated. A 2.5-inch fire hose with a 4-foot pipe

nozzle, at a pressure of about 40 pounds, was first used. The progress for

the first day gave reason for optimism, but thereafter continued trouble was

encountered. Instead of the soft mud in which the divers had ordinarily

worked, and which washed freely with a hose, it was found that under a thin

layer of hard sand and mud, there was a bed of hard blue clay mixed with some

sand in which the submarine was buried. The consistency of the clay was such

that a moderate water pressure had no effect on it. It was found impossible

to raise the pressure on the 2.5-inch hose, as the diver was unable to

withstand the reaction of the hose and lost control. After the first day's

work, it was found imperative to raise the pressure to cut the clay. To

permit this, the last length of fire hose was replaced by a 50-foot length of

1.5-inch wash deck hose with a pipe nozzle of the same diameter, and with this

reduced size the diver was able to hold a pressure up to 70 pounds, which

would cut the clay when the nozzle was held close against it. With this

nozzle work was continued throughout the fall.

Another unpleasant discovery was the fact that the clay and the sand were so

heavy that, unlike mud, they refused to stay in suspension when cut and

settled again in the tunnel within a foot or two of the nozzle. This feature

was aggravated by the small size of the water jet, which was unable to set up

any appreciable current in the tunnel as it advanced under the boat. As a

result of this, the diver was compelled, after cutting ahead a little, to turn

his nozzle and wash all sediment backwards out of the tunnel. Consequently

only a small portion of the diver's time on the bottom was spent in actual

cutting ahead.

Finally weather conditions through October and November were such that diving

was ordinarily impossible more than two days in succession, after which two or

three days might elapse before diving could be resumed. It was found on

returning after each storm that the bottom currents had either partly or

completely filled the tunnel with heavy hard-packed sand, which had to be

washed out before any new cutting was possible.

The above factors, complicated by an insufficient and a decreasing force of

divers, prevented driving a tunnel through during the fall operations.

Several times success seemed near, with the divers approaching or even

touching the keel, but each time bad weather caused a suspension, and

practically all work had to be done over again when tunneling was resumed.

After the first three diving days, sufficient knowledge of the troubles

existing in sealing up and in tunneling was gained to make it evident that the

10 experienced deep-sea divers would not be able to finish the job before

winter set in. An attempt was made to bolster up the force by using some of

the shallow-water men, sending them down in company with more experienced

divers. This policy was tried out on October 28, but the results were

unfortunate. The first man sent down failed to orient himself and did

nothing. The second man apparently was paralyzed with fear, fell off the

submarine, and was found wandering on the bottom after having fouled the lines

of another diver. This second man contracted a severe case of bends that

night from which he nearly died, and which kept him in the hospital for over

five months. A third shallow-water diver sent down late that day wasted the

dive of his partner, who was compelled to put in his entire dive, keeping his

mate from being washed away by the current or fouling his lines, and

consequently accomplished nothing himself.

The experience of this day proved conclusively that the diving course at

Newport does not fit a man to dive in work of this kind. In confirmation of

this fact, it was noted that of some 20 shallow-water divers present, none

desired to work on the job, all apparently realizing fully their lack of

training. As there was now neither time nor opportunity for training these

men, it was felt that time did not exist for the small number of experienced

men present to complete

----------------------------------------------------------------------- Page 17

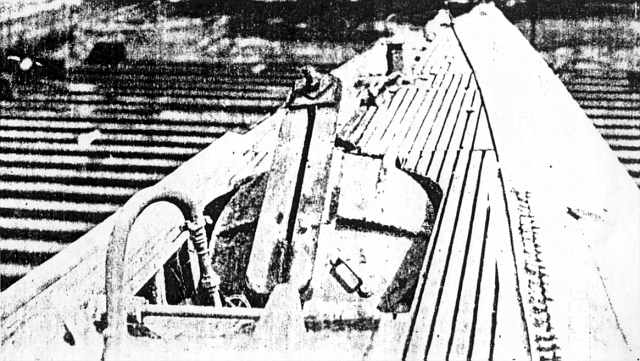

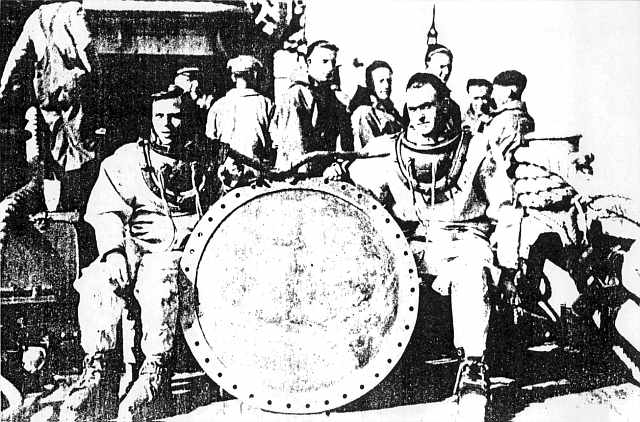

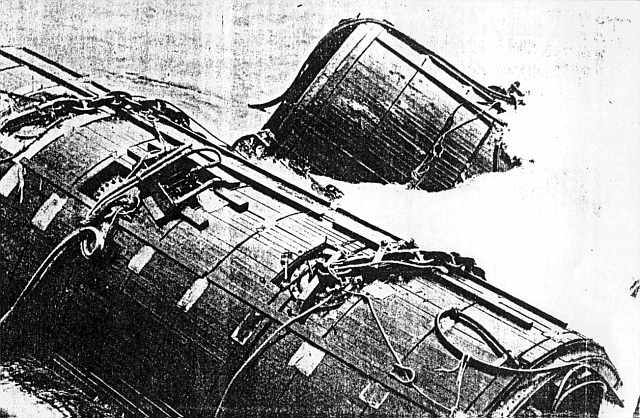

Figure 6: Channel strong back securing motor room hatch.

----------------------------------------------------------------------- Page 18

the job; by the middle of November this was seen to be a certainty. However

it was determined to do as much as was possible while the weather permitted.

To seal off the motor room, Eiben and Wilson entered from the engine room and

closed all necessary valves including the ventilation valve. Later they

closed the motor room door and sledged down the dogs. To discharge the water,

the drain valve in the forward bilges (pl. 1) of the motor room was opened,

there being a nonreturn valve on the bilge suction. In the engine room a

valve bonnet on this drain line was removed so that water could be forced from

the motor room to the engine room but not in the reverse direction. To admit

air, Kelley and Anderson removed a bolt through the top of the motor room,

tapped out the bolt hole, and secured a 0.75-inch connection for a blowing

hose. To prevent blowing open the motor room hatch under internal pressure,

an external strong back was made and bolted down over the hatch, as shown in

Figure 6.

On November 7, the air was put on the motor room to test it out. Considerable

water was expelled, when air started to blow out the ventilation main in the

superstructure.

Inquiry of the "S-51" survivors disclosed the fact that the drain valve on

this line in the motor room was defective and could not be effectively closed,

though they had not previously reported this trouble.

To remedy it, the motor room door was opened, the drain line disconnected, and

the valve (1.25 inches) sealed with a pipe plug. The door was resecured after

considerable difficulty, on November 15, and on November 18 another attempt

was made to blow the motor room. After the water had gone down a few feet,

the air started to escape through the ventilation valve, which was reported by

the divers to be chattering like a relief valve with the air being released in

gusts. This valve was closed and secured by the internal locking gear, but

this locking gear, even when set up to the limit, was unable to hold the valve

on its seat against a few pounds pressure. Nothing further could be done with

this compartment during the fall operations.

The second compartment attacked was the C.O.C. To seal this compartment

required the substitution of two salvage hatches for the regular hatches in

the conning tower and the gun access trunk, as the original hatches were

unable to hold an internal pressure. There was further required the closing

of numerous valves inside the C.O.C. and the closing of the two doors leading

to the battery room and the engine room.

As a preliminary, the hatch on the gun access trunk was opened as previously

described. The hatch on the conning tower was open at the time of sinking.

Handling the salvage hatches presented a new problem. Each hatch was made of

steel plate 1.25 inches thick, with a heavy strong back and bolt running

through it, and with a long length of 4-inch suction hose attached to the

underside about as shown in Figure 7. Each hatch weighed around 700 pounds

assembled.

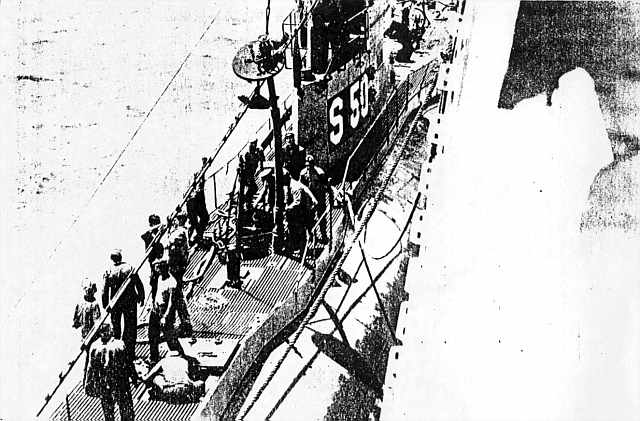

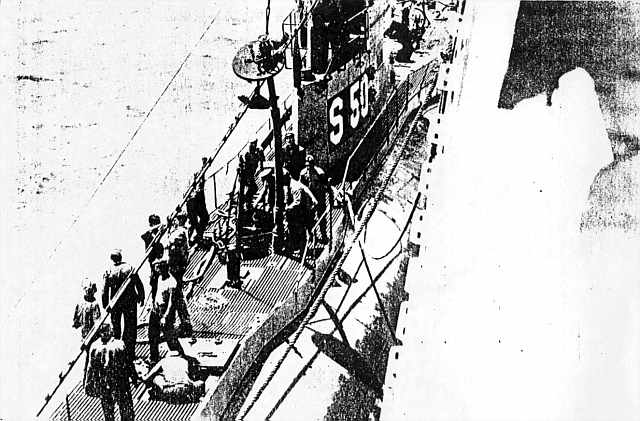

After a rehearsal on the "S-50" it became evident that the hatches could not

be suspended from the surface while the divers endeavored to install them, as

the up-and-down motion was too much to allow the divers to work. It

consequently became necessary to provide a means on the submarine boat over

each hatch for handling it. For the conning-tower hatch a heavy oak timber

provided with an eyebolt was secured over the bridge where it plumbed the

hatch cover and the hatch itself was handled by a half-ton chain fall secured

to the eyebolt in the timber; using this rig the conning-tower hatch was

hooked onto the chain fall after it had been lowered in the bridge inclosure

and was installed and set up by two divers, Frazer and Smith, in one dive.

Having secured the conning-tower hatch, another long oak plank was attached

across the timber already in place over the bridge, with the end of the new

timber projecting forward of the bridge enough to plumb the top of the center

of the gun access hatch. With this rig in place and the chain fall ready, the

hatch was lowered from the surface boat, guided down by

----------------------------------------------------------------------- Page 19

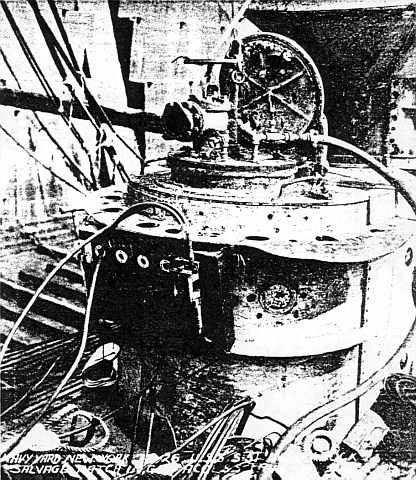

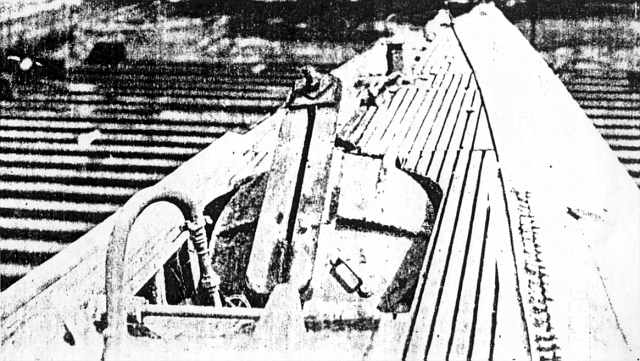

Figure 7: Engine room salvage hatch.

Practice on "S-50". (Note 4-inch hose.)

----------------------------------------------------------------------- Page 20

a line secured to the side of the gun access trunk. As the hatch neared the

submarine it was dragged over by the divers, who entered the suction hose into

the trunk and fed it down until the hatch was landed when the surface line was

let go by the divers. The chain fall was then hooked into the strong back

bolt and the hatch was thereafter handled from the chain fall by divers.

Considerable difficulty was encountered with this hatch in getting it

adjusted, on account of the slope of the submarine boat, but this hatch was

also successfully installed by Frazer and Smith in one dive. However, it

appears that the exertion of handling this heavy weight while plumbing the

hatch was such that Frazer strained his heart and it was discovered that

further diving by Frazer was out of the question. (Gun access hatch, fig. 8.)

With both hatches in the C.O.C. sealed up, the next attempt was to close the

doors. Two divers entered the battery room and went aft along the passage to

the crew's quarters toward the forward C.O.C. door and found the passage

blocked by mattresses and bunks. An attempt was next made to enter the C.O.C.

through the after door from the engine room. The first pair of divers who

tried this entrance were unable to squeeze through. The second pair of divers

on the same attempt had to quit because four underwater lamps burned out on

them during one dive while inside the submarine boat. A third attempt to

enter this door, made by Wilson and Eiben proved successful. The two men got

part way in the C.O.C., cleared away a bunk which had washed into the C.O.C.

from the battery room forward, and then found a clear though congested passage

through the remainder of the C.O.C. By working forward they reached the

forward C.O.C. door, which was found jammed with wreckage but which was

cleared and closed by the divers. The necessary valves to seal up the C.O.C.

were next closed by the same pair of divers.

On a previous dive the divers noted that one of the air banks showed about

2,000 pounds of air in the C.O.C. An attempt was consequently made to open

all the Kingston valves in the main ballasts, using the master controller in

the C.O.C. to operate the air motors at the individual valves. The divers

opened the master control, but none of the air motors functioned. As a result

of this the Kingston valve for No. 3 port tank was opened by hand from the

C.O.C. and the Kingston valves for ballast tanks 4 and 5, port and starboard,

which were accessible from the engine room, were opened by hand from the

engine room. None of the gear for operating the Kingston valves on the

remaining ballast tank were accessible from the inside of the boat, due to

wreckage.

Having opened the Kingston valves on port ballast tanks 3, 4, and 5, on the

next dive Wilson entered the C.O.C. again and adjusted the valves on the air

manifold so as to blow down these three ballast tanks, using the ship's own

compressed air. Another diver was stationed outside the submarine to observe

the discharge from the Kingstons. Air was turned on all three tanks at once

and the gauge inside the boat started to drop in pressure immediately. The

diver outside noted that a stream of muddy water was being discharged from the

Kingston in each one of the three tanks. The tanks were blown for about 30

minutes, when the air on the gauge inside the ship dropped so low as to render

further blowing inadvisable. All air valves were closed and the diver came

out. None of the three ballast tanks had commenced discharging air, so none

of them were dry. It was estimated that all of them were from one-half to

two-thirds blown down.

A rubber hose was found through the after door of the C.O.C. running from a

connection in the engine room to the ice machine located under the deck in the

C.O.C. As this hose prevented closing the door, it was cut by the divers and

gagged on both sides of the cut. The divers then closed the after door on the

C.O.C. and dogged it down.

A hose for blowing the C.O.C. was secured to the connection provided on the

salvage hatch already installed and air was turned on the C.O.C. After

building up a pressure of 3 or 4 pounds in excess of the bottom pressure at

the point of discharge, air started to blow

----------------------------------------------------------------------- Page 21

Figure 8: Gun access salvage hatch in position.

(Note air connections.)

----------------------------------------------------------------------- Page 22

in gusts from the C.O.C. It was evident that in spite of being locked from

the interior the ventilation valve in this compartment was operating in the

same manner as the valve in the motor room. As this occurred at about the

same time - that is, late in November - nothing could be done during the

remainder of the fall operations.

About the middle of November divers worked in the engine room on the fuel-oil

manifolds, setting the valves and rigging air connection to blow the contents

of the fuel-oil tanks, of which there were two groups, one forward and one

aft. The after group of oil tanks were blown first, the contents being

discharged through a hose led to the surface. It was found that the after

group contained nothing but water, all of which was blown out until air was

discharged. The connections were then shifted to blow the forward group,

which was done a few days later. From the forward group of oil tanks there

was discharged first water, then oil, and finally water again, until air was

discharged.

Late in October an attempt was made to lower the first pontoon. Divers passed

reeving lines of 21-thread manila under the stern of the submarine, which was

clear of the bottom. On these as guide lines there were hauled heavier

manilas and then two 1-inch wire lines. The pontoon was to be lowered with a

15-fathom shot of 2.5-inch anchor chain hung from each hawse pipe, each chain

being held at the top of the hawse pipe by a heavy bolted clamp similar in

design to those used on the "F-4". The wire hauling lines were secured to the

lower end of each one of the chains. The pontoon was to be lowered from the

surface, using a 6-inch manila line at each end.

Flooding of the pontoon was started as in previous practice with these

pontoons on the "F-4" and the "U-111". The pontoon sank until it was

practically awash, when it tended to submerge one end first. Some time was

spent in juggling with the vent valves and the air connections on each end of

the pontoon in an endeavor to level the pontoon and make it go down

horizontally. This was not successful, as whenever the pontoon was made heavy

enough to submerge as a whole one end always dropped first. As no more time

was available for holding the pontoon at the surface, the weather getting

worse, the pontoon was finally permitted to flood until it had negative

buoyancy and was then lowered over the side on the 6-inch lines. As the

pontoon went down a few feet it grew heavier and it became quite evident that

the 6-inch lines could not hold the weight. To prevent the lines from

breaking, an endeavor was made to pay them out fast; but in spite of this,

first the line on the after end and then the line on the forward end of the

pontoon broke in quick succession; later it was found that the pontoon had

descended to a depth of about 50 feet when this happened. The pontoon

thereafter fell freely to the bottom. Fortunately the "Falcon" was being held

clear on one side of the submarine and the pontoon landed away from the

submarine about 50 feet on the starboard quarter. The hauling wires with

which it had been expected to guide the pontoon in position against the

submarine had slacked off and fouled themselves around the submarine. After

some days' work these wires were finally cleared and the pontoon was blown dry

and brought to the surface. It was evident that the methods previously used

in lowering and handling pontoons in shallow were not applicable in the open

sea.

The "Falcon" proceeded to Narragansett Bay where, in shallow water, using

another pontoon, an attempt was made to lower evenly. It was again

demonstrated that as soon as the pontoon had taken in enough water to

submerge, between the loss of external water plane and the free water surface

inside the pontoon (the pontoon at this time being two-thirds full of water),

it retained no longitudinal stability, and the slightest inclination toward

one end or the other would cause that end to drop and the water on the inside

to flow to that end and make the pontoon go down one end first. Two solutions

seemed possible; one was to allow the pontoon to flood completely at the

surface and provide means of lowering it which could stand the full load of

----------------------------------------------------------------------- Page 23

40 tons. The second was to discover at what point the pontoon had taken in

sufficient water to reduce its internal free water somewhat and consequently

its lack of stability. If the pontoon were held reasonably level by the

lowering lines, one end would not have a tendency to float up while the other

end dropped and took all the load. It was felt that if such a condition could

be found the pontoon could be flooded to that condition, the flood valves

closed with the pontoon slightly submerged, and the pontoon then lowered.

After some calculation and considerable experiment in Narragansett Bay, it

appeared that with a negative weight of the pontoon of 10 tons the internal

free water plane was sufficiently reduced to make the pontoon reasonably

stable provided it was not permitted to exceed a moderate inclination. To

handle the weight of 10 tons there was required a large factor of safety for

dynamic conditions and for the probability of exceeding the designated weight

while flooding. It appeared that nothing less than a 12-inch manila line

would be satisfactory.

By this time it was too late in the season, however, to do anything further

about lowering pontoons alongside the "S-51".

Meanwhile the mate to the first pontoon lowered, which had been moored to the

buoy near the wreck on the day of lowering the first pontoon, was torn away by

a bad storm and washed ashore about 30 miles away on a beach in Buzzards Bay.

An independent expedition was sent out on the "Sagamore", which after some

difficulty managed to pull the pontoon down the beach and float it again,

where it was taken back to Newport.

After the middle of November the weather became so bad that diving was

possible only at infrequent intervals and the water became extremely cold.

From the 21st of November until the end of the month diving was impossible

altogether until the 30th of November when an attempt was made to dive. On

this occasion, of three divers sent down two had to be hauled up because their

air hoses froze up with ice from the moisture in the air being pumped down to

them and completely cut off their air supply. At the same time only 4 divers

out of 10 who started the job were still in good condition for work. It

appeared that operations could not be continued successfully.

An attempt was made to hire civilian divers to augment the force, but only

three men were found who were willing and qualified to work on the job, except

those of the wrecking company which had handled the rescue operation

originally, and the latter were not employed.

Considering the unsuitability of the weather, the impracticability of being

able to work more than 1 day in 10 or 15, and the lack of divers, it was

decided, on December 6, to suspend operations for the winter and all vessels

of the salvage squadron proceeded to their usual stations. The mooring buoys

were removed by the Lighthouse Service and two marker buoys, one can buoy and

one lighted buoy, were left to mark the position of the wreck. The pontoons

were left moored to the docks at the torpedo station, Newport.

Before the shallow-water divers who were attached to the "Falcon" temporarily

were detached and sent to their permanent stations, all of them, about 20,

were put in the recompression chamber on the "Falcon" and the pressure was run

up to 80 pounds, being the equivalent of about 180 feet depth of water. As a

result of this pressure test, it was found that 12 of the men were capable of

standing the pressure and appeared suitable material for deep-sea divers.

The diving personnel on the "Falcon" scattered to their regular stations with

the exception of the few men who were kept at New York to overhaul diving

equipment during the winter and with the exception of Chief Torpedoman Kelley,

who was retained as an instructor for the diving class which was immediately

started, using the 12 men just selected.

During the months of December and January these men were given daily work in a

diving tank at the navy yard, New York, where they were required to use air

tools of every description and do various jobs under water on pipe joints,

cutting out rivets, and handling weights, the idea being to make the men

thoroughly familiar with tools under water and to get them into

----------------------------------------------------------------------- Page 24

the habit of working under water without conscious effort as regards the

proper adjustments of their diving rig. In the meanwhile a series of

experiments was also carried on looking toward the development of a

practicable under-water cutting torch, the torch previously available for use

by the Navy having failed to operate on every occasion during the fall

operations when it was tried. The torch experiments were carried out under

the direction of Lieut. Commander Edward Ellsberg, who at the same time took

the diving course with the other shallow-water divers.

Meanwhile considerable attention was given to the method of rigging the

"Falcon" for lowering pontoons, and a careful mathematical investigation was

made of the stability conditions of a pontoon while being flooded on the

surface and while being lowered.

At the end of January the members of the diving class were considered

sufficiently trained and were sent to the south to join the "Falcon" again for

the purpose of actually diving in deep water. Unfortunately, the operating

schedule of the fleet was such that during the first month that these men were

aboard the "Falcon" no opportunity whatever arose to permit them to dive. As

a result of this condition the men were all returned to the navy yard, New

York, about the middle of March, where their training in the tank was resumed,

followed shortly by diving in the basin of the navy yard where, on account of

the mud bottom and the opacity of the water, diving conditions were somewhat

harder than in the tank.

About the middle of April the diving squadron was reassembled at the navy

yard, New York, and all equipment which had been landed was taken aboard. All

divers were recalled from their permanent stations and rejoined the "Falcon".

The total diving force with which the expedition was equipped at the start of

the spring operations was 25 men, of whom 10 were the original divers, 12 were

members of the new diving class, 2 were divers from the fleet not previously

available, and 1 was the yard diver from the navy yard, Boston.

The "Falcon" sailed from the navy yard, New York, on April 23, 1926, and

proceeded to Narragansett Bay, where the next three days were spent practicing

on sinking a pontoon in deep water. It was found that the calculations were

correct and that a pontoon flooded down to a negative weight of 10 tons could

be lowered slowly to the bottom, held at any depth desired, and finally placed

in any position required before actually landing. The total time taken in

lowering the pontoon could be indefinitely extended, and in practice a pontoon

was held for periods of over 30 minutes. By marking the 12-inch lowering

lines with distinctive marks, at each fathom of their length, it was possible

to maintain the pontoon in a horizontal plane at all times during lowering.

To accommodate the wire hauling lines which were required around the submarine,

the bulwarks of the "Falcon" were cut away in two places on each side and new

steel chocks made on the "Vestal" were installed.

At the same time all members of the new diving class were given an opportunity

to dive in 130 feet of water and work on the pontoon as it was landed on the

bottom. The new divers all passed this test in deep water satisfactorily with

the exception of one man, who had trouble clearing his ears and who was unable

to stay on the bottom as a consequence.

The underwater cutting torch was also tested out on the bottom in deep water

satisfactorily, a steel bar 3.75 by 3.75 inches in section being rapidly cut.

Having made sure that practicable means of lowering pontoons was available,

the "Falcon" sailed on April 26, 1926, from Newport for the scene of the

wreck. Arriving at its approximate location it was found that the two marking

buoys which one week before had been sighted in proper location and close

together were now separated by a distance of over 5 miles. As the weather was

hazy at the time, it was not possible to determine by sights of lighthouses on

the horizon which buoy was correct, if either of them was. An attempt was

made to get radio compass bearings from stations in the vicinity, but these

plotted about 3 miles away from each buoy. Assuming that the more northerly

buoy was probably correct, sweeping was started by the "Falcon" in its

vicinity, but no results were obtained that day.

----------------------------------------------------------------------- Page 25

The next day the "Vestal" arrived. With clear weather it was possible from

the high bridge on the "Vestal" to sight three lighthouses and get an accurate

fix of the northerly buoy. Compared with the original fix of the wreck

obtained last fall, the wreck appeared to be about one-quarter of a mile west

of the position of this buoy. Sweeping was consequently concentrated in this

area, using grappling hooks. Late in the afternoon of the second day, one of

the grappling hooks made a hard strike and a diver descending the grappling

line found himself on the deck of the submarine. The grappling line was

immediately cast loose from the grapnel and made fast to the submarine, after

which the "Falcon" replanted the moorings in the same locations as during the

fall operations. An inspection of the submarine boat showed no change in

position from that when last sighted in November. The vessel had not settled

any deeper in the bottom nor changed her list or trim, nor had there been any

silting up around the hull. There was a slight marine growth over parts of

the hull, but no great amount. Diving was prevented by rough weather during

the next few days, but on the 30th of April, 1926, the weather was fair and

the "Falcon" took position for lowering the first pontoon on the port quarter

of the "S-51". Divers passed two small reeving lines under the stern on which

were hauled through heavier manila lines and then a pair of 1-inch wire lines

for hauling. These wires were secured to the lower ends of a pair of chains

suspended through the pontoon hawse pipes, the chains being held on top of the

pontoons by bolted clamps.

Unfortunately, just after the pontoon went awash and before the flood valves

had been closed, a splice in the wire strap holding the forward lowering line

opened up under no special strain, and as a result of this accident the

pontoon tore free and sank to the bottom, end on. As before, the "Falcon" was

holding herself a little clear to port, so the pontoon in landing hit the

bottom about 30 feet outboard of its designated position. The next day this

pontoon was lightened up on the bottom by blowing out some of the water and

was then hauled over to its position against the port quarter of the

submarine.

The wire hauling lines, having pulled the chain under the submarine, were rove

through the hawse pipes of the second pontoon on the surface and this pontoon

was then lowered on the two wires as guides. This pontoon was sunk somewhat

lighter than intended, with the result that it landed alongside the submarine

standing on its end rather than horizontally. As a result, one of the chains

unrove through the hawse pipe. The matter was rectified by lightening the

pontoon and bringing it to the surface, after which it was resunk. The second

time it went down evenly and landed in the horizontal position as intended.

The torch was then used for the first time in actual work on the job. The

chains were hauled through the pontoon hawse pipes for a predetermined amount

after which a stud in the link just above the hawse pipe was burned out of

each chain and a nickel steel toggle bar 40 inches long and 3.75 by 3.75

inches in section was slipped through the chain and locked in position by a

long half-inch bolt on each side of the chain link. (See fig. 9.) When this

had been completed, the lowering lines were cast loose and the hauling wires

were burned free of the chain and taken up.

Meanwhile work was recommenced on the forward tunnel at frame 46, using the

same size hose and nozzle as during the fall operations.

A special inclinometer was made and taken down by one of the divers to measure

the heel of the ship. A measurement was taken just forward of the conning

tower and it was found that the "S-51" was listed over exactly 11.5 degrees to

port.

Work was now commenced on lowering a pair of pontoons on the bow, and reeving

lines were passed under that part of the bow which was clear of the bottom.

The forward reeving line, however, slipped out three times from under the ship

owing to the rise of the forefoot. To remedy the situation Chief Torpedoman

Kelley went down with the torch and reaching down 2 feet through a hole in the

deck burned in half the wire holding the mushroom anchor. This

----------------------------------------------------------------------- Page 26

Figure 9: Bow pontoons. (Note nickel-steel toggle bar through link,

locked in position by 1/2-inch bolt each side.)

----------------------------------------------------------------------- Page 27

dropped the anchor from its place under the keel forward until it rested on

the bottom, and in this position its shank, which still protruded into the

hawse pipe, formed a trap behind which the next reeving line was passed and

which prevented any further slipping out of the reeving lines.

A pontoon was then rigged and lowered on the starboard bow in the same manner

as those at the stern, and later in the same day another pontoon was lowered

on the port bow. This was the first instance in which two pontoons were

lowered in one day. These pontoons were secured by the divers in the same

manner as those at the stern.

During a storm early in May which came up during the night while the "Falcon"

was lying moored over the submarine, one of the tugs, the "Iuka", drifted down

on the "Falcon", and in getting clear the "Falcon" was compelled to cut most

of her mooring lines, while the "Iuka" fouled her anchor in the bow pontoons

on the "S-51" and was then forced to slip her cable.

As a result of this, when the storm cleared considerable work was necessary to

clear the fouled anchor and chain, to replace the descending lines which had

been carried away, and to recover the lost mooring lines.

On May 11, 1926, after the longest dive made, up to that time, 2 hours and 20

minutes, Eadie and Wilson working from opposite sides of the submarine both

managed to drive their tunnels down to the keel of the submarine. Eadie

pushed his foot under the keel to the other side to which Wilson secured a

small line which Eadie hauled back with his foot and the first line was thus

passed. A second reeving line was then pulled through, tied to the first

line, and the two lines cleared of each other.

On this same day 16 divers made a dive, being the maximum number of divers who

went down on one day during the entire operation. On the next good day

preparations were made to sink a pontoon on the port side abreast frame 46.

Manila lines, 4-inch, were rove through the tunnel as hauling lines for the

1-inch wires. The wires were hauled down and secured to the chain hanging

from the pontoons at the surface as usual. However, when all was in readiness

and the 4-inch lines were hauled in to pull the wires through, one of the

4-inch manila lines was cut in half by the starboard bilge keel of the

submarine when apparently running freely and without strain. The remainder of

the day was spent in an endeavor to recover an end of this line but

unsuccessfully. Meanwhile the weather changed and in a heavy sea the pontoon

alongside became a serious menace and had to be cast loose from all lines and

towed away. The next day it was found that one wire reeving line was fouled

on the bottom and had to be cleared. To replace the line which had been cut

it was necessary for the divers again to work through the tunnel and push a

new line through, this time with a small pipe 8 feet long as a lance to carry

it through under the keel. After some difficulty this was accomplished and a

new 1-inch wire was rendered through. About 7 p.m. work began on sinking a

pontoon on the port side. The pontoon was lowered successfully and was held

at a point about 30 feet above the bottom, where the chain should have started

to render through under the keel; but in spite of the maximum pull that could

be given on the hauling wires by the "Falcon", the chain failed to render.

Two heavy manila hawsers, 6-inch and 8-inch, were then secured to the wire

hauling lines, and the ends of the hawsers sent over to the "Iuka", which was

anchored about 100 yards broad off the beam, with the idea of getting a flat

hauling lead which might make the chains render more easily under the keel of

the "S-51". The "Iuka" heaved on both lines with her quarter-deck winches but

without result. A diver was sent down to inspect conditions on the bottom and

found the pontoon in its proper position about flush with the deck of the

submarine and with the two wires on the opposite side of the submarine leading

out flat and taut toward the "Iuka", but no chain was through under the keel.

The diver came up and the "Iuka" then started ahead on her main engines

gradually working up to full power, but in spite of this she was unable to

haul the chain through.

45129-27--3

----------------------------------------------------------------------- Page 28

The "Iuka" then slacked off the 6-inch manila line to get her entire hauling

strain on the 8-inch line. After about five minutes under these conditions,

the 8-inch line parted, throwing the entire strain suddenly on the 6-inch

line, which also parted. As nothing more could then be done, the pontoon was

lowered the remainder of the way to the bottom.

During the following two weeks various methods were tried to haul the chains

under the keel, including the placing of tapered wood blocks under the keel as

fair leaders. Various attempts were made to clear the first link from the

keel with crow-bars and several more attempts to haul the chain, using the

"Iuka" to haul. In every instance whenever a strain came on the chain the

first link would be brought hard up against the angle of the box keel, which

hung about 16 inches below the hull, and the chain would then bind securely

and could not he freed. Owing to the close quarters, a diver having to work

in a small tunnel and in an extremely difficult position, the divers were

never able to clear the chain. Finally, after the last attempt at hauling had

resulted in tearing the quarter deck winch out of the "Iuka", it was concluded

that a different method would have to be used, and the pontoon was brought to

the surface, together with the chains. Having done this, the position of the

wire hauling lines through the tunnel was carefully checked, after which the

chains were removed from the pontoons. The eye of the first wire hauling line

was shackled in to the end of one of the chains, using a Boston design

detachable link for a shackle. Over the end of the wire was then fitted a

special steel cone which gave a smoothly faired surface from the 1-inch wire

around the outer diameter of the first link, with no angles to catch on the

box keel. With this rig the first chain was independently lowered and passed

through the tunnel under the keel without difficulty, where it was equalized

with the same amount of chain on each side of the hull. The second chain was

lowered in the same manner. There being no pontoon to contend with at this

time, the divers were able to work on the bottom while the chains were being

lowered and to guide the chains through the tunnel. Having secured the

chains, they were then held up as shown in Plate 3, and a pontoon was lowered

on the port side until it was about 20 feet clear of the bottom, in which

position a pair of divers went down on the pontoon, checked its location, and

then rode the pontoon the rest of the way to the bottom. Here the divers cast

off all lines and inserted and secured the locking hers. The mate pontoon,

meanwhile, was brought out from Newport and was lowered and secured the same

day.

This method of handling the chains and the pontoons was seen to be

considerably superior to the manner in which the pontoons had been handled

before - that is, with the chains lowered with the first pontoon. The reason

for the original rig was that the only means of securing the chains in the

hawse pipes of the pontoon was by means of a steel clamp made in two halves,

weighing about 300 pounds, and secured by four 1.5-inch bolts. Such a rig was

extremely difficult to handle and probably could not be secured without

auxiliary rigging in the way of chain falls or lines to the surface. In

shallow water, where a diver could work all day, such means were available.

In deep water, where his time on the bottom was very limited and extreme

exertion was likely under the heavy pressure to affect him unfavorably (as

actually happened in the case of Frazer), it was considered best to cut this

work in half by securing the pair of chains to the first pontoon by making up

the clamps on the surface, leaving only the work of clamping the chains to the

second pontoon.

However, when the use of the torch made possible the removing of studs and the

insertion of a locking bar at any desired point, it became possible to

eliminate the clamps. This was first done only in the case of the second

pontoon of each pair, but was obviously applicable to both pontoons, and the

further use of clamps was wholly discontinued. It might casually have

appeared that all studs might have been burned out on the surface originally,

but there was considerable danger in such a practice of the chain kinking up

if the studs were missing while the chain was being handled under the

submarine boat, and as such a kink would insure

----------------------------------------------------------------------- Page 29

the parting of the chain in a load, it was considered safer to burn off the

studs where wanted, rather than taking a chance on burning out a large number

to insure getting an open link on the hawse pipe.

Early in the spring operations, on May 11, 1926, work was started to seal off

the ventilation main leading to the C.O.C., the engine room, and the motor

room. The motor room was first attempted, as the ventilation main leading to

this compartment could be most readily reached of the three compartments. The

deck of the submarine just forward of the motor room was removed, and the deck

beams covering the ventilation main were then burned clear by Chief Torpedoman

Kelley. Work was then started on unbolting both flanges of a section of this

12-inch main for the purpose of blanking it off on the motor room side. After

some days all the bolts were removed from the after flange, but several of the

bolts in the forward flange were practically inaccessible due to their

location close alongside the engine air induction valve. After several

attempts by divers to get at these bolts, it was determined, after an

inspection by the salvage officer, that there was no need to unbolt both

flanges. Consequently, a wire line was tied around the pipe near the unbolted

flange and on heaving from the "Falcon" the pipe was torn out of the ship, the

forward flange breaking off the pipe while the unbolted flange came clear.

The joint left in the ship was then scraped clean by divers and a new blank

flange, which was immediately made, was securely bolted on. (See figs. 10,

11, and 12.)

After blanking off the ventilation main to the motor room, air was turned on

to blow it dry, and divers reported a good stream of water being discharged

through the nonreturn drain line into the engine room. After blowing about

half an hour, a stream of air bubbles came to the surface over the forward end

of the motor room. A diver's examination showed that a butt in one of the

upper strakes of the shell on the starboard side was open over a sixteenth of

an inch (the vessel was single hull throughout the motor room) and a steady

stream of air was escaping from a length of about 2 feet at the upper portion

of the butt.

It was evident that the leak was due to defective workmanship originally, as

there was no evidence of damage or strain in that vicinity. Apparently a

poorly fitted and wide-open butt had been made tight by splitting the edges of

the plates and bringing the feather edges of the two plates together. Between

corrosion and an internal pressure part of the feather edge had now given way,

causing a bad leak.

To remedy this, Eadie and Eiben were sent down with strings of lead wool made

by twisting together lengths of fine lead fuse wire. They calked this lead

wool into the open butt until the space between the two plates was completely

full, using ordinary hand wood calking tools for the job. Eadie then took a

standard air-driven chipping and calking hammer and, using a fuller, proceeded

to recalk the plates themselves in the usual manner. This calking job was

complicated by the fact that each time the trigger was pulled the stream of

air escaping from the hammer set up such a cloud of bubbles in the water that

it was no longer possible to see the work clearly and the diver had to be

guided by his sense of touch and general skill. When the air pressure was put

on the compartment, the part of the butt which had been recalked was found

tight, but new leaks had developed over the remaining length of the butt (as

is usual even in surface work) and Eadie was compelled to recalk the entire

butt with the air hammer. This effectively stopped all leaks in this

location.

In this calking job, the surface air pressure was kept at 150 pounds. The net

pressure at the hammer was between 80 and 90 pounds, taking account of hose

friction. On examination of this job later with the vessel in dry dock, the

calking could not be distinguished from the other calking done while the ship

was building.

Air was again turned on the motor room and the water driven down a few feet

farther, when another stream of air bubbles appeared, this time near the stern

of the submarine and aft of the motor room itself. On a diver's examination

of this new leak it was found that about

----------------------------------------------------------------------- Page 30

Figure 10: Section of 12-inch air supply line to motor room,

removed by divers.

----------------------------------------------------------------------- Page 31

10 feet from the stern there was a large dent in the top of the boat in way of

the tiller room; in this dent one rivet was completely pulled through the

shell and the adjoining rivet was partly pulled through. Air was escaping

freely from these two places.

The tiller room was a small compartment abaft the motor room, connected with

the latter by a manhole about halfway down the bulkhead. It was evident that

this manhole was open (which was not known definitely before) and that the air

in the motor room, having driven the water down to the level of the top of the

manhole, was now escaping via the tiller room leaks.

To seal the leaks, a lead plug was cast to the size of the open hole and

fitted with a tapered oak cone driven into its base to act as an expander.

When this plug was inserted in the hole, the wood plug brought up against the

frame bar inside, and resulted in spreading the lead plug inside the hole

while the lead was being hammered down by the diver outside. The result was a

firmly secured flush lead plug which was entirely tight and proof against

jarring loose or being torn away by towing lines during later salvage

operations.

To seal the partly pulled rivet (the rivet itself was solid and in no way

loose) the diver drove soft pine plugs into the open parts of the countersink

so that the wood was firmly jammed in; then trimmed the wood off flush to

prevent lines from tearing out any of the wood filling. This rivet showed

pinhole leaks afterwards through the pine, but they were of no consequence.

The reason for the dent in the shell was never definitely discovered. The

location was far removed from all collision damage and could not have been a

result of the submarine hitting the bottom. It is believed that one of the

vessels engaged in the original rescue operations dropped anchor over the

"S-51" and that the anchor landed on the stern, dented it in, and bounced

clear.

The work of sealing the motor-room leaks was completed early in June, and the

pressure again applied; No further leaks appeared on the outside of the vessel

in the vicinity of the motor room, but when the water level inside had been

forced down to the point where it reached the shaft stuffing boxes in the

bulkhead between the engine and the motor rooms, air started to escape in

considerable quantity through the stuffing boxes into the engine room. At

this point, the motor room was about two-thirds dry. It was only by sending

all the air the "Falcon" could supply into the motor room that it was possible

to drive the water lower; the moment blowing ceased, the air below the shaft

lines would escape and the motor room refill to this level.

Inquiry of the officers on the "S-50" brought out the information that on all

submarines it was impossible to keep interior shaft stuffing boxes tight as

the vibration due to the close proximity of the engines quickly wore the

packing to a considerable clearance.

No attempt was made to tighten up the stuffing boxes, as they were practically

inaccessible to a diver; further it was considered that when the engine room

was sealed up and blown dry, air leakage around the shafts would be of no

consequence. If, however, on this job the engine room, instead of the battery

room, had been the bilged compartment, this leakage around the shafts would

have been a serious matter.

Having sealed up the motor room ventilation valve by blanking it off,

consideration was given to the same procedure for the ventilation valves in

the engine room and the C.O.C. The main engine air induction valve, having

had its bonnet previously removed in the process of closing the valve, was

quickly sealed from the outside by bolting a steel strong back across the

valve body and pressing a heavy oak block firmly down on top of the valve disk

to hold it on its seat.

The battery exhaust valve which discharged into the engine room and the

ventilation supply valve which opened into the C.O.C. presented different

problems. Both valves were closed by their internal locking gear, but it was

now known that this was ineffective. It appeared possible to get at a section

of the battery exhaust main in the superstructure and

----------------------------------------------------------------------- Page 32

Figure 11: 12-inch supply pipe to motor room

sealed by cover plate installed by divers.

----------------------------------------------------------------------- Page 33

blank it off, though with more difficulty than in the case of the motor room.

The line to the C.O.C., however, was so covered by other pipes and buried

inside the structure of the periscope shears as to be practically inaccessible

for blanking off from the exterior of the boat.

A start was made on removing the deck over the engine room, to get at the

battery exhaust main at the same time as work was proceeding on unbolting the

ventilation main to the motor room. The latter operation, while successful,

took so much time that work was suspended on the engine room and a search made

for methods requiring less diving.

It was noted that each one of the compartment ventilation flapper valves had a

1.25-inch drain valve screwed into its body just above the flapper disk. In

the case of the motor room, such a drain valve had previously caused

considerable trouble by leaking and had to be plugged. It now appeared that

through these drain-valve openings a cement mixture might be injected into the

ventilation-valve bodies on top of the closed flapper valves, which on

hardening would permanently seal the valves closed.

To carry out this scheme, a special elbow, to get into a confined space, was

made on the "Vestal" to suit the drain-valve connection in the C.O.C. This

was tried on the "S-50". The door from the engine room to the C.O.C., which

had been closed during the fall operations, was undogged and reopened after

some difficulty (the gasket stuck). Eadie, Wilson, and Eiben then proceeded

to install the cement connection, but found conditions on the "S-51"

sufficiently different to prevent installation, as less clearance existed on

the "S-51". After modification, the fitting was finally installed, but with

great difficulty, as the water in the C.O.C. was so black from particles in

suspension and from dead water throughout the winter that, even with a

submarine lamp, vision was possible not over 6 inches, and the work had to be

done by sense of touch in a cramped space. Conditions were so bad that the

lamp itself was invisible unless held within 6 inches of the diver's

faceplate.

Meanwhile experiments were being carried out on the "Vestal" to determine the

best cement mixture. The primary requisite was to obtain a cement that would

harden under salt water; the secondary problem was to obtain a cement mixture

that would flow freely through 250 feet of 1.25-inch-diameter hose, pass

through a number of valves and fittings, and that would still not be too

liquid to set firmly.

Several brands of standard Portland cement were experimented with, but their

hardening qualities under salt water, except in very thick mixtures, was

extremely poor. A special bauxite cement, furnished by the Atlas Lumnite

Cement Co., was tried and found to be extremely satisfactory. A neat mixture

of two parts of this cement to one part of water by volume was found to be

thin enough to insure flow, while its setting properties under salt water were

excellent. The use of Lumnite cement in this proportion is strongly

recommended for all future salvage jobs where cement is required.

For injecting the cement, the "Vestal" made a steel tank tested to 200 pounds,

with a quick-opening handhole on top for filling, test cocks on the side for

determining the cement level, and a discharge connection tapering from 3

inches to 1.25 inches at the bottom. Using 200 feet of hose leading to the

bottom of the sea into a piece of 12-inch pipe, a full-scale experiment was

carried out on the "Vestal" to test the apparatus and the mixture, the cement

being forced out by 150 pounds of air pressure on the tank. About five hours

after injection, the pipe was hauled up and the cement was found already to

have set moderately hard. It was kept submerged in salt water and by the next

day had set solidly.

The hose and the apparatus were taken to the "Falcon", where the divers ran

the hose inside the submarine and connected the last short length to the

fitting on the C.O.C. ventilation valve. When all connections had been made,

the cement was mixed on the "Falcon", and two charges forced through, being

about four times as much cement as was required to fill the valve body. The

divers then uncoupled the hose section near the C.O.C., sent up the remainder

of the hose, and a few days later closed and dogged down the door to the

C.O.C.

Go to section: 1 | 2 | 3

| 4 | 5 | 6

|

Return to: | Contents Page | Index |