Figure 1: Derricks attempting to raise stern.

(Note slings.)

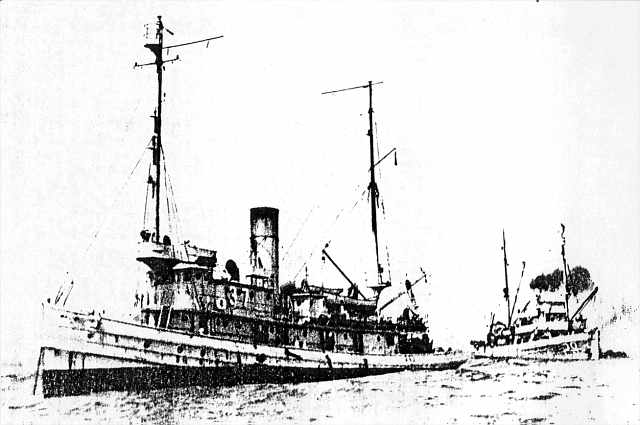

Figure 2: Derricks attempting to raise stern.

(Note maximum lift available.)

Figure 3: Divers on fall operations.

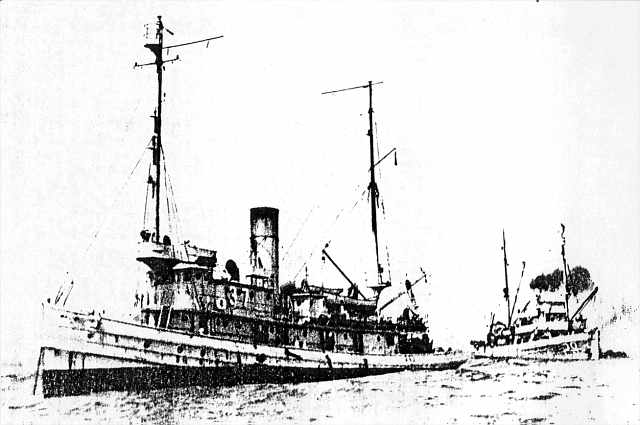

Figure 4: "Iuka" holding "Falcon" in position over wreck.

REPORT ON SALVAGE OPERATIONS, "S-51"

The U.S.S. "S-51" was sunk at 10.24 p.m., on the night of September 25, 1925,

in collision with the steamship "City of Rome". The "S-51" was struck at

frame 54, at an angle of about 40 degrees abaft the port beam, and a hole

about 30 inches wide, extending from the port bilge keel to the superstructure

deck, was made. This opening came about midway of the battery room.

At the time of collision, "S-51" was acting as a surface vessel, steering a

steady course, of about northwest, at a speed of 11.5 knots. The sea was

moderately rough, and all hatches were secured, except the conning-tower

hatch. Except for the officers and men on watch, the crew had turned in. The

"S-51", following normal procedure, was ventilating outboard, with main air

induction and battery exhaust valves open in superstructure, ventilation

valves open in all compartments to external ventilation mains, and all

interior doors open for interior circulation. The Diesel engines were drawing

air both from the engine air induction valve on the external ventilation main

and through the conning tower hatch via the open door between engine room and

control room.

As an immediate result of the collision, a large volume of water poured into

the battery room, giving the ship a trim by the head and a list to port. The

"S-51" appears to have planed under as a consequence of this trim and to have

submerged in considerably less than one minute. Under the increasing

pressure, water flooded the boat very rapidly and the crew was unable, against

the rush of water, to close any of the interior doors. Three men, asleep in

the battery room, escaped through the conning tower hatch, and were picked up

alive about an hour later. Seven men, two officers and two men forming the

bridge watch, and three others who were inside the boat, but managed to get

through the conning tower hatch, were washed overboard. These seven were seen

swimming, after the "S-51" sank, by the men who were later rescued, but no one

of these seven was found when the "City of Rome" finally managed to get a boat

overboard. The body of one man in this group was found alongside the hull

later; the bodies of the other six were never recovered.

The position of the "S-51", as reported several hours later by the "City of

Rome", proved to be several miles in error, but no special difficulty occurred

in locating the wreck, as a considerable oil slick was soon discovered by the

vessels searching, and a moderate stream of air bubbles in this slick gave the

exact location. The "S-51" was found in the open sea, about 15 miles south of

Brenton Reef Lightship, and about 14 miles east of Block Island, the depth of

water being 132 feet.

The torpedo range diving boat from the torpedo station, Newport, brought the

first divers. About noon, September 26, 1925, the first diver went down and

found the "S-51" heeled over about 13 degrees to port, lying on a hard level

bottom, and buried about 5 feet. The diver made a careful inspection along

the deck and found air in moderate quantities escaping through all hatch

covers, these being closed but evidently not set set up from inside for a full

due. The diver hammered on all hatches and listened intently but was unable

to hear anything from inside the boat. It was therefore reasonably certain

that all hands inside were dead.

In the absence, however, of conclusive proof, rescue operations were attempted

under the direction of the forces afloat, the commander, control force, being

in charge. Two derricks, the "Monarch" of 150 tons capacity, and the "Century"

of 100 tons capacity, being the two largest derricks available, were hired

from a commercial salvage company. It was assumed that life inside could

exist only if the crew had succeeded in closing off one or more of the after

------------------------------------------------------------------------ Page 2

compartments, either the motor room aft, the engine room just forward of it,

or perhaps both. If these compartments were buoyant, a 250-ton lift would

raise the stern; if they were flooded it could of course have no effect.

The two derricks were towed to the harbor of refuge at Point Judith; their

unsuitability for open sea work was immediately demonstrated when they were

held inside the harbor of refuge for a number of days awaiting calm weather.

Several starts were made from Point Judith in the interim, but on each

occasion, after getting several miles to sea, further progress was considered

dangerous and the derricks were towed back to harbor.

A calm day finally arrived, the two derricks were towed out and hooked on to

wire slings passed around the stern. The derricks took their maximum combined

lift, 250 tons, without result except to bend both propeller shafts, the

wrecking company's divers having passed their slings outboard, instead of

inboard of the shafts. The derricks then cast loose and were hurriedly

returned to the harbor of refuge. (See fig. 1.)

For the benefit of those making similar attempts in the future, it should be

noted here that the two derricks employed in this operation would have been

unable to bring the stern to the surface even had they developed the requisite

lift. (Fig. 2.) Neither derrick had sufficient drift on its fall to lift the

stern all the way to the surface. Had the stern started, the two derricks

would have lifted it about two-thirds of the way and then been unable to do

anything except lower away again. No means were at hand for hanging off the

load while the derricks shifted purchases; it is further questionable whether

the derricks could safely have been kept in the open sea long enough for such

an operation even if equipment had been provided.

The raising of the stern having failed, it was deduced that the stern was

flooded, and that no life existed inside the boat. To verify this, using an

electric arc, the salvage company's divers now melted out the securing studs

in two hatches, the torpedo room forward, and the engine room aft. Both

compartments were found flooded. No entry was made in the motor room aft.

At this point, the rescue operations were abandoned, and the forces afloat

ceased further activities. The wrecking company was discharged from further

connection with the work.

The Bureau of Construction and Repair undertook the problem of salvaging the

ship. As is usual in such circumstances, the customary number of visionary

plans was submitted from all over the country, and a number of offers received

from irresponsible individuals and companies. The bureau also received from

the wrecking company engaged in the rescue operations an offer to undertake

the salvage of the ship. After careful consideration of this offer, the Navy

Department and the Bureau of Construction and Repair decided to have the Navy

undertake the job itself.

To the commandant of the third naval district, Rear Admiral C. P. Plunkett,

United States Navy, was assigned the task. The commander of the submarine

base, New London, Conn., Capt. E. J. King, United States Navy, was detailed

by the commandant as the officer in charge, salvage operations, and took

charge of the salvage squadron. Lieut. Commander E. Ellsberg, Construction

Corps, United States Navy, was assigned by the commandant as salvage officer,

in charge of technical and diving operations. The following vessels formed

regular units of the salvage squadron:

U.S.S. "Falcon", diving ship, Lieut. H. Hartley, commanding. The "Falcon" was

a mine sweeper specially fitted with air compressors and a recompression

chamber for diving and salvage work.

U.S.S. "Vestal", repair ship, Capt. W. V. Tomb, commanding. The "Vestal"

furnished repair facilities, boat service, supplies, and berthing for salvage

personnel.

U.S.S. "Sagamore"; seagoing tug, Chief Boatswain G. Cregan, commanding. The

"Sagamore" acted as a portable mooring; also for towing pontoons.

------------------------------------------------------------------------ Page 3

Figure 1: Derricks attempting to raise stern.

(Note slings.)

------------------------------------------------------------------------ Page 4

U.S.S. "Iuka", seagoing tug, Chief Boatswain Augustine, commanding. Same

function as "Sagamore".

U.S.S. "Bagaduce", seagoing tug, Chief Boatswain Mangan, Lieutenant Rundquist,

Lieutenant Rickertts, commanding at different periods. "Bagaduce" served part

time, same function as "Sagamore".

U.S.S. "Penobscot", tug, Chief Boatswain's Mate Ashland, commanding. The

"Penobscot" acted as dispatch boat, making a daily round trip to New London

for mail and supplies.

U.S.S. "S-50" Lieut. Commander M. Lenney, commanding, submarine. The "S-50"

did duty during the fall operations as a model boat for divers' rehearsals;

same service at intervals during spring operations.

In conference with the Bureau of Construction and Repair, it was decided to

raise the "S-51" through a combination of restored internal buoyancy, and of

external buoyancy to be furnished by pontoons. The "S-51", as shown by the

inclining experiment, had a surface displacement of 1,001 tons and a submerged

displacement of 1,230 tons. In the surface condition, liquid weights amounted

to about 80 tons. As a submerged wreck, wholly flooded, the buoyancy of the

hull structure, engines, lead batteries, sheathing, etc., was assumed to be

that of steel, and a deduction of 120 tons was made on that basis. This

brought the dead weight to be lifted to 800 tons. This weight was checked

against the weight obtained by considering the quantity of water admitted to

each compartment, taking account of permeability and proved to be in

reasonable agreement. The weight was probably a little less than 800 tons;

but as that figure appeared to be on the safe side, it was thereafter used.

It was further believed from the divers' reports and a study of the plans that

it was possible to make buoyant three main compartments -- the central

operating compartment (C.O.C.), the engine room, and the motor room. In

addition, it was believed that main ballast tanks, port and starboard, Nos. 3,

4, and 5, could be blown dry. As possibilities, but not so probable, it was

hoped to dry the forward and after groups of oil tanks, the two bow buoyancy

tanks, the forward trimming tank, and the water round torpedoes' tank. As

bare possibilities, it was considered that main ballast tanks Nos. 2, port and

starboard, might be dried, and that No. 1 fuel oil tank and the "A" main

ballast tank might also be made dry.

No attempt was to be made to obtain buoyancy, for the reasons given, in the

following spaces:

Battery room -- This compartment was the one in which the collision occurred.

No reasonable hope existed of sealing up the large and ragged gash extending

through inner and outer hulls.

Torpedo room -- On sinking, the "S-51" hit the hard bottom, bow first, with

considerable way still on. As a result, the hull had buckled at bulkhead 43,

where the structure changed from single to double hull, making a point of

discontinuity in strength. At this bulkhead there were two deep

circumferential wrinkles showing on the shell plating, these standing out from

the shell about 4 to 6 inches along the upper hull and fading out gradually

toward the keel. The after bulkhead of the torpedo room was thus badly

damaged in its shell connections. In addition, practically every air and

drainage line to the torpedo room was severed at the point of collision,

making air-tightness hard to obtain.

Port ballast tank No. 1. -- Opened to the sea by the collision. Its forward

bulkhead was also damaged by the wrinkling at bulkhead 43.

Starboard ballast tank No. 1. -- This tank had its forward bulkhead at

bulkhead 43 damaged in the wrinkling of the shell, due to buckling.

Port ballast tank No. 2. -- This tank was considered a probable loss, as its

forward bulkhead at frame 61 was bent in, due to collision damage. An attempt

was to be made to use this tank if it proved reasonably tight on trial.

------------------------------------------------------------------------ Page 5

Figure 2: Derricks attempting to raise stern.

(Note maximum lift available.)

------------------------------------------------------------------------ Page 6

Starboard ballast tank No. 2. -- This tank was in good condition and was to be

made ready for blowing. However, it was not to be blown down unless its mate,

No. 2 port, first turned out to be usable, as otherwise the submarine would be

given a bad port list in the raising process.

Miscellaneous variable tanks under the C.O.C. -- There were a number of

auxiliary ballast and adjusting tanks located under the control room on which

nothing was attempted. The individual tanks were small and the work required

on each tank out of proportion to the buoyancy obtainable in any one tank.

Owing to the double hull structure, these tanks could not be reached from the

outer shell in way of the main ballast tanks; underneath the submarine they

rested in the clay, and a special tunnel would be required to reach them.

A careful study was made of the attainable buoyancy in each compartment,

taking into account a port list of about 13 degrees and the amount of water

which could not be expelled even from a sealed compartment on account of

irregularities in the tank tops and the impossibility of getting the bottom of

the spill pipes to the lowest points in the compartments. (See pl. 1.)

The buoyancies of the compartments which were regarded as certain were:

-------------------------------------------------------------------------------

| | Per cent |

Compartment | Total | of buoy- | Net

| buoyancy | ancy at- | buoyancy

| | tainable |

-----------------------------------------------+----------+----------+---------

C.O.C. ........................................| 90 | 60 | 54

Engine room ...................................| 110 | 80 | 88

Motor room ....................................| 130 | 80 | 104

Port ballast tanks 3, 4, 5 ....................| 62 | 75 | 46

Starboard ballast tanks 3, 4, 5 ...............| 62 | 75 | 46

| | +---------

| | | 338

-------------------------------------------------------------------------------

Buoyancies of the compartments which were regarded as probable were:

-------------------------------------------------------------------------------

| | Per cent |

Compartment | Total | of buoy- | Net

| buoyancy | ancy at- | buoyancy

| | tainable |

-----------------------------------------------+----------+----------+---------

Forward group oil tanks .......................| 43 | 75 | 32

After group oil tanks .........................| 33 | 75 | 25

Bow buoyancy tank No. 1 .......................| 80 | 75 | 6

Bow buoyancy tank No. 2 .......................| 11 | 75 | 8

Forward trim tank .............................| 10 | 75 | 8

Water round torpedo tank ......................| 6 | 75 | 4

| | +---------

| | | 83

-------------------------------------------------------------------------------

As improbable, but worth attempting, were the following group:

-------------------------------------------------------------------------------

| | Per cent |

Compartment | Total | of buoy- | Net

| buoyancy | ancy at- | buoyancy

| | tainable |

-----------------------------------------------+----------+----------+---------

No. 2 port main ballast .......................| 19 | 75 | 14

No. 2 starboard main ballast ..................| 19 | 75 | 14

No. 1 fuel oil tank ...........................| 12 | 75 | 9

No. A main ballast ............................| 7 | 75 | 5

| | +---------

| | | 44

-------------------------------------------------------------------------------

From the above table it appeared that the total internal buoyancy which could

be relied on amounted to 350 tons. To raise the submarine, it was required to

provide at least 800 tons, together with a margin against accidents and a

sufficient reserve to allow the pontoons to float above the surface with an

adequate water plane for stability on the long tow to New York. In addition,

there existed a powerful but undetermined suction effect between the submarine

and its clay bed, and to break it required both excess buoyancy and the

ability to manipulate

------------------------------------------------------------------------ Page 7

the submarine before lifting, otherwise the "S-51" could not be torn free. It

was believed that a 25 per cent reserve was the minimum for safety, which

meant that at least 1,000 tons of buoyancy must be provided. As it was

assumed that about 350 tons of internal buoyancy was the most that could be

relied on, an external buoyancy of 650 tons was required, and to obtain it 8

pontoons of 80 tons net lift each were required.

Such buoyancy as might be obtained in the "probable" and in the "improbable"

groups, amounting to a maximum of 83 tons for the first and 44 tons for the

second, would constitute additional reserve.

The suction effect was checked over. At its worst, with the vessel in

intimate contact with the clay bottom under an absolute pressure of 73 pounds

per square inch, it appeared that to overcome suction by direct lift would

require a pull of 8,000 tons. Instances were on record of the suction effect,

notably on a submarine which having bottomed in deep water found itself unable

to rise even after more than enough water had been expelled from the ballast

tanks to give it positive buoyancy. This vessel finally freed itself by

sallying back and forth with the propellers, thus allowing water to work under

the hull and break the suction. For the "S-51" it was decided to break

suction, first, by rolling the ship to starboard and, second (and mainly), by

lifting her stern first, thus allowing the water to work forward under the

hull.

It was further realized that it would be impossible to control the trim while

in the raising process so as to bring the ship up on an even trim; if left to

chance either end might come up first. No substantial objection could be

found to raising the vessel one end at a time, and as the general arrangement

of the ship together with the location of the undamaged compartments favored

it, it was determined to lift the "S-51" stern first, and all pontoon

locations, sling locations and lashings were selected with this in mind. (See

pl. 5.)

Several objections were received from various unofficial sources to raising

the vessel one end first; none were based on a clear understanding of

conditions. It can be definitely stated that neither by derricks, pontoons,

by partial restoration of internal buoyancy, by total restoration of internal

buoyancy, or by any combination of these methods could the "S-51" have been

brought up both ends together; any attempt to control the rise of either bow

or stern by laying out anchors or other weights to check the movement would

have been both futile and dangerous.

As the only possible means of control to reduce the angle the boat might take

in the raising process, it was first decided to use a pilot pontoon secured at

each end, halfway to the surface, the idea being that when the pontoon on the

end which rose first broke the surface and lost its lift, the further rise of

that end would be checked while the other end was being lifted to the same

level; the further blowing of the submarine was to give enough additional

buoyancy to bring the boat up the rest of the way, still rising one end

first. The theoretical advantage of this method was that the maximum angle of

the boat was reduced from 25 degrees to perhaps 10 degrees to 12 degrees. The

practical difficulties in connection with its use were that as the set of main

pontoons attached to the submarine rose part way to the surface, the air in

them would expand, force water out of the pontoons, and make them increasingly

lighter as they came up. This might result in a greater gain in buoyancy in

the main pontoons than was lost when the pilot broke the surface. If such

were the result, that end of the submarine would keep on rising and the pilot

would be wholly useless as a check. This probability, together with the large

amount of additional work required for attachment and the fact that the pilot

pontoons would be obstructions after the "S-51" rose, lead to the abandonment

of the idea. The two 60-ton pontoons which happened to be available,

ex-"F-4", and which were first assigned for use as pilots, were kept on hand

as a reserve in case it was found impossible to seal up any of the major

compartments. They were, however, never used for any purpose.

It was calculated, and subsequent events proved correct, that the "S-51" could

safely be handled at the maximum angle, between 25 and 30 degrees. In case of

another salvage operation

------------------------------------------------------------------------ Page 8

where the ratio of depth of water to length of boat is such that this angle

would be much exceeded, it is believed that the best solution is to set the

main pontoons at such a height above the submarine as to limit the angle to

about 30 degrees then the pontoons first break the surface at one end. With

all pontoons afloat, the vessel can then be towed to more shallow water until

she bottoms and all pontoons reset as low as possible.

A study of the structure, hatches, and piping systems of the "S-51",

especially of the external ventilation system and its valves, showed that the

vessel was not especially suited to the use of compressed air as a salvage

agent. The hatches were all designed to seat with the sea pressure outside

holding them in place. Against an internal pressure they had only a light

strong back; set up on a relatively small central bolt which was inadequate to

resist a third of the necessary internal pressure without letting go; in

addition the strong back could not be set up hard enough to prevent air

leakage under a very small excess internal pressure -- 2 or 3 pounds.

Under these conditions, pumps at first glance appeared more suitable, as their

use would result in a pressure inside less than the outside pressure and would

thereby help to seal the hatches and the ventilation valves. But pumps

brought in additional difficulties. Steam was out of question as a source of

power, owing to the long lead and the cold water which would condense it on

the way down. Air was practically ruled out, as the "Falcon's" compressors

could deliver only 150 pounds on the surface on no discharge; against a back

pressure of 60 pounds, the net pressure was only 90 pounds which would be

reduced by friction of hoses to about 70 pounds. If a small pump was used,

this pressure could be maintained, but the pump would be a toy in comparison

with the job; if a large pump were employed, the "Falcon" would be unable to

supply enough air to keep the net pressure up to even 20 pounds and the pump

would be ineffective.

Electricity as a source of pump power appeared more satisfactory.

Direct-current pumps were undesirable due to the danger of short circuiting

the pumps if the casings leaked. There were available a number of special

submersible salvage pumps with 4-inch suction and discharge; these required a

special motor generator to supply them with alternating current, but there was

no danger of the pumps themselves short-circuiting, as the design called for

water circulating through the coils. The cable connections to the surface

required absolute water-tightness, however, or a short circuit would result.

These pumps would discharge 100 tons an hour against a maximum head of 80 feet.

As the head of water here was about 132 feet, it was obvious that even the

alternating-current pumps were inadequate to the job without making up the

difference in head by an internal pressure equal at least to 52 feet of water,

or about 23 pounds. There would be required air connections as well as

pumping connections to each compartment.

It will be seen that the depth made the use of pumps of any description

difficult, and it was consequently decided to use compressed air alone as the

first resource. However, as a stand-by, a complete outfit of the

alternating-current submersible salvage pumps was taken, the "Falcon" was

fitted out with the special motor generator, a special foundation for

attaching each pump to the deck of the "S-51" was made and fitted on the

"S-50" as a model, all salvage hatches were fitted with connections to which

the pumps could attach their suctions, and electric cables made up in 300-foot

lengths for the pumps were provided. A duplicate motor generator installation

was provided on the "Vestal" in case it turned out that the "Falcon's" regular

generators proved inadequate to carry the ship's load and also run the motor

generator.

The expedition was thus fitted out to use compressed air alone if the

compartments could be made to stand internal pressures; or to use pumps if it

was found that they could be sealed only against external pressures. In any

case, compressed air alone would have to be used on the pontoons and all

ballast and other tanks on the "S-51".

------------------------------------------------------------------------ Page 9

The pontoon question required immediate attention. Two 80-ton pontoons and

two 60-ton pontoons, originally built for use on the "F-4" in Honolulu Harbor,

were available at Norfolk, and were shipped to New York. They were known to

be unsuitable as they stood, since they were designed for use only in 45 feet

of water. On test at 25 pounds internal pressure, the heads bulged 1.5

inches, and further pressure appeared dangerous. As the pressure at the

bottom of this job was about 58 pounds, the new pontoons were built with

heavier heads, heavier bulkhead stiffeners, and internal tie angles, all

designed to resist the full pressure. The new pontoons were successfully

tested under a hydrostatic pressure of 55 pounds. The "F-4" pontoons were

then reinforced in a similar manner by extra stiffeners and internal bracing,

so that they also were able to stand the new pressure on test.

The pontoons as thus built or strengthened were able, when blown dry at the

bottom, to rise suddenly to the top, where the internal pressure now became an

unbalanced bursting pressure, without any danger of being ruptured. This

safety feature was not generally known; it avoided a point of failure much

stressed by amateur experts who predicted trouble due to bursting of

pontoons. As an additional safeguard, each pontoon was provided at the bottom

of each end with a simple spring loaded relief valve, 6 inches in diameter.

These valves were adjusted to blow at an excess internal pressure of between 5

and 10 pounds. As the pontoons were intended to be used with the 6-inch flood

valves also open, this gave four 6-inch openings for blowing off air while

rising. Taken in conjunction with the known strength of the pontoons, no

fears were ever felt for the safety of the pontoons during the lifting process.

The structural arrangement of the pontoons and their fittings for blowing and

venting are shown in Plates 8 and 9 (footnote 1). It will be noted that each

pontoon is divided into two parts by a central athwartship water-tight

bulkhead. A 1-inch blowing connection is fitted near the top center of the

pontoon for each half, a 0.75-inch vent connection is fitted at the top near

each end. A 6-inch flood valve with an extension rod is fitted in the bottom

of each head; alongside it is the 6-inch relief valve. A 12-inch hawsepipe

extends from top to bottom of each half, with the hawsepipe castings strongly

backed up by internal brackets to take the load.

For transverse stability, each pontoon was given about 2 tons of cement

ballast, spread across the bottom. For protection in handling and in towing,

each pontoon was sheathed with 3.5 inches of yellow pine, laid edgewise, and

the valves on the heads were protected by 12-inch timbers. For the protection

of divers and others in walking on the pontoons, two longitudinal cleats of 2

by 4 inch planks were secured on each side near the top, and proved of great

value. Heavy clips were riveted to the heads for towing and lowering.

The general design of the pontoons followed that of the "F-4" pontoons, except

as modified for extra strength. It was shortly discovered that the type of

pontoon was generally unsuited for the work in hand, especially in deep water,

and should not again be used without numerous changes. At the period,

however, there was no time to design new pontoons, and the "F-4" type of

pontoon was supposed to be satisfactory. The principal defect was lack of

longitudinal stability when submerged (this led to numerous difficulties in

handling and a tremendous amount of extra work); the next most important

defect was loss of attainable buoyancy in the high end of the pontoon when

inclined. This was a serious problem on the day of actual raising, when this

lost buoyancy amounted to at least 150 tons.

The navy yard, New York, undertook the immediate construction of six

additional 80-ton pontoons. These were finished and delivered in about four

weeks.

Each pontoon had a gross lift of 120 tons, a weight of 40 tons, and a net lift

of 80 tons.

The next problem was divers. Civilian divers willing to work in deep water

were exceedingly scarce, there being no more than 5 or 6 along the Atlantic

coast. It was decided to proceed wholly with naval divers, and a check of

those available indicated that 30 divers could

-------------------------------------------------------------------------------

1) Plates 8 and 9 show pontoons as altered after the salvage operations in

order to obtain additional longitudinal stability. (See Appendix D)

----------------------------------------------------------------------- Page 10

be obtained from the fleet and from various naval stations. Thirty men whose

records individually that they had qualified as divers were ordered to report

for the job; of these about half came from the fleet, then in southern

waters. The schedule of operations was made out on the assumption that most

of the men could dive; it was shortly discovered that most of them could not

dive in deep water, and the number of actual divers qualified to work in deep

water was reduced to 10 (See fig. 3.) This was a wholly inadequate number to

carry on the work with any hope of completing it in the six weeks period

before winter broke. That the 30 men provided were not deep-sea divers was

not made plain until after operations had commenced. It was then too late to

do anything except keep on and accomplish as much as was possible with the

forces in hand. For the benefit of those undertaking deep-sea salvage jobs in

the future, disappointment should be avoided by making sure that the divers

provided are qualified for actual deep-water work. Further, unless at least

20 such divers can be obtained, it should be realized that the work (and the

expense) will be unduly dragged out. It is probably better not to undertake

the job at once, but to organize a diving class, using the available divers as

instructors; when the students have reached a suitable stage of diving

ability, work may commence. There will be opposition to this policy, as

considerable hysteria attends every case of loss of a submarine and there will

be pressure for immediate action. However, civilian divers do not exist in

sufficient numbers; the Navy will always have to provide its own, and the best

results will be obtained by training enough men first rather than by rushing

in and wearing out the few real divers at hand trying to cover a deep-water

job with an inadequate force. This was promptly demonstrated by the history

of the "S-51".

The "S-51" was sunk on September 25, 1925. Rescue operations by outside

wreckers lasted until early in October. The decision to undertake salvage,

using the Navy resources, was made about October 7, 1925, and the "Vestal",

then in Cuba, was ordered north immediately. The "Falcon" was sent to New

York for fitting out with electric pumping equipment and other material. The

"S-50" was sent to New York and placed in dry dock, where she was carefully

studied, inside and out, by all divers.

On October 14, 1925, the "Falcon" sailed for Block Island. Arriving at the

scene of the wreck, the "Falcon" first planted 6 moorings around the wreck, 1

dead ahead, 1 right astern, and 2 off each beam. These mooring anchors varied

from 3,000 to 6,000 pounds each. To each anchor was secured a short length of

1.25-inch chain. To the chain, a mooring line consisting of two parts of

0.75-inch steel wire rope 40 fathoms long was attached. A mooring buoy was

attached to the wire lines. At first can buoys borrowed from the Lighthouse

Service were used, but one of these sank and the others were soon superseded

by log buoys obtained from the navy yard. As unmooring especially was usually

carried out in bad weather, the type of buoy was important, and spruce logs

cut from an old mast were found very satisfactory and were easy for a boat to

work alongside. Several of the buoys cut from heavier woods proved

unsatisfactory, as they barely watched, and completely disappeared under a

strain on the mooring line. Such heavy buoys were replaced by large

cylindrical steel buoys of 5-ton buoyancy, originally designed to float

submarine nets.

A seventh mooring, with a 10,000-pound anchor, was planted by the derrick

"United States" to the southward, about one week later.

The mooring lines from the "Falcon" to the buoys were 7 or 8 inch manila

hawsers, each with a pelican hook at the outer end. In mooring, the "Falcon"

normally steamed in headed either north or south and brought her bow close

aboard the windward mooring. A small boat ran out the first mooring line and

secured the pelican hook to the buoy, using a split pin on a lanyard as a

toggle pin. Another windward line was run immediately and the "Falcon" paid

out on these while the boat ran out three more lines.

A normal moor called for five lines, two to windward, one ahead, one astern,

and one to leeward for centering purposes. While the "Falcon" ordinarily

moored parallel to the "S-51", heading

----------------------------------------------------------------------- Page 11

Figure 3: Divers on fall operations.

----------------------------------------------------------------------- Page 12

north or south as weather required, there were many occasions on which such

headings were impossible and the "Falcon" was then moored athwart the wreck.

Great skill in mooring was exhibited by the "Falcon", which usually ran the

five lines and centered herself in 30 minutes. The best time in mooring was

12 minutes.

Unmooring was a difficult operation, as it always took place either in

darkness or in bad weather and many times in both. To unmoor, a small boat

ran along the buoys in succession the lee buoys first, and the bow man tripped

the pelican hooks by catching the lanyard on the toggle pin with his boat

hook. Hauling the lanyard first pulled the pin out. As the lanyard was

attached at its other end to the locking link; on the pelican hook, a jerk

usually pulled the link clear and tripped the hook. As in heavy weather the

boat always plunged up and down, considerable skill in maneuvering was

required of the boat in unmooring. A standard Navy 36-foot or 40-foot motor

launch was first used, being the only boats available, but these were clumsy

and slow for the job. Later a 26-foot motor whaleboat was borrowed from the

Coast Guard, and too much praise can not be spent on the performance of this

boat in the open sea and its handiness for the mooring and unmooring job.

Such a boat is indispensable for future operations and should not be omitted

from the equipment of the salvage ship.

The "Falcon" was always moored to form a lee on one side, from which side

diving was carried on. In case the wind and sea increased during the day, the

"Vestal" was moved around to windward and anchored as a breakwater. To assist

in holding the "Falcon" in position, it was customary in bad weather to anchor

the "Sagamore" and the "Iuka" about 150 yards off on the windward bow and

quarter and run out two additional mooring lines, one to each ship. (Fig. 4.)

As a variation, in very bad weather, the "Sagamore" and "Iuka" were often

anchored in tandem to windward the first tug holding up the second one, and

the second tug holding the line to the "Falcon". In this manner, having

started diving, it was never broken off due to a change in wind or sea, unless

the wind got beyond force 5, when holding the "Falcon" became impossible. As

a result of this policy, the number of diving hours, short as they were, was

at least doubled over ordinary practice, and the length of the job was

correspondingly shortened.

Diving on the salvage operations commenced on October 16. The first efforts

were directed toward cutting away the loop antenna, the clearing lines, and

the wireless aerials. This was necessary to avoid fouling the divers in the

submarine's overhead rigging. This gear was cut with a special sharpened

cutting hook attached to a line from the surface. Clearing away took three

days, as the hook had to be resecured for each cut; no faster means was

available at the time.

Two descending lines of 4-inch manila were secured to the submarine, one to

the muzzle of the gun forward, and the other to the railing near the engine

room hatch aft. About 20 feet of slack was allowed on each line; three small

cork buoys were attached to the surface end of each line to float it. Later

as many as four descending lines were used. The descending lines usually

lasted two to three weeks, when they chafed away, and at least one line was

ordinarily found missing after each storm.

It was now desired to provide the reeving lines for the pontoon slings.

Dipping a wire line under the bow and sawing it aft was first suggested. This

method did not appear applicable, as the depth of water rendered the leads bad

for sawing and would result in fouling lines; the bottom was hard clay, which

did not lend itself to sawing; the line would have to be worked 60 feet aft

under the deeply embedded hull for the first pair of reeving lines and 100

feet aft for the second pair; it was certain that the box keel or the sharp

bilge keels would cut the sawing line in half very quickly, and, finally, no

diving work could be undertaken while sawing was under way. It was decided to

wash a tunnel under for the reeving lines, which, while difficult, would

permit the interior work on the submarine to proceed at the same time.

----------------------------------------------------------------------- Page 13

Figure 4: "Iuka" holding "Falcon" in position over wreck.

----------------------------------------------------------------------- Page 14

In sealing up the interior, it was intended to make each main compartment

entirely independent of all other compartments as regards water-tightness.

The value of this policy was demonstrated on the final raising day. To

accomplish this, however, required additional work, and the sealing problem

was especially complicated by the supply and exhaust ventilation mains in the

superstructure. As shown by Plate 2, the supply main opened into every space

except the battery room, and the exhaust main ran from the battery to the

engine room. There was no possibility of closing the valves from these mains

in the torpedo room or the battery room. Consequently, closing the main air

inlet valve and the main exhaust valve in the periscope shears (even if these

could be sealed against internal pressure, which was not possible) would do

nothing toward sealing up these ventilation mains. It was required therefore

that the ventilation valves in each compartment be effectively and separately

sealed aft.

Frazer and Smith boarded the "S-50" and were carefully rehearsed on closing

the valves in the engine room. They then descended to the "S-51", where

Frazer slipped through the engine room hatch while Smith remained outside on

the deck of the submarine to tend Frazer's lines. This was the usual

procedure whenever anyone entered the submarine.

Frazer closed some 20 valves in the engine room as per schedule but the

largest valve of all, the 25-inch main engine air induction, a quick-closing

lever-operated valve, closed only three-fourths of its travel, and several

attempts failed to make it close farther.

The same day tunneling was started at frame 46, Bailey and Michels beginning

on the port side. Their progress was fair, using at first a 2.5-inch fire

hose with moderate pressure.

Several days were spent in attempting to clear away the obstruction in the

engine air induction valve, but without result. As the valve had to be

closed, it became necessary to remove the decking over the valve in the

superstructure; tear up the steel deck beams over the valve, using a 6-inch

manila line to the "Falcon's" winch for the purpose; unbolt forty 0.75-inch

nuts which held down the valve bonnet; break the joint and lift off the

300-pound bonnet. All of this work, done by Frazer and Smith, was finished on

November 2, when we found a piece of 1-inch steel pipe, 3 feet long and much

corroded, jammed under the valve disk. This pipe, evidently left in the vent

main during building, had been washed into the valve by the rush of water when

the "S-51" sank. (See fig. 5.)

Meanwhile work was started on sealing the C.O.C. The most direct means of

entrance seemed to be through the gun access hatch, which was fitted as an

escape hatch but was found closed. To open this hatch, the following

procedure was carefully rehearsed on the "S-50" and then carried through on

the "S-51"; Kelley and Anderson smashed the glass port on the starboard side

of the gun access trunk. Reaching through this 4-inch hole with a specially

twisted bar having some five different bends in it to clear obstructions

inside, Kelley hooked the latch holding down the cover and tripped it; then

inserting a small cutting hook, he seized the 0.25-inch wire secured to the

under side of the hatch and cut it. The hatch flew open. The divers found

two bodies in this trunk, which they sent up, the two men having been trapped

there through inability to operate the escape features of the trunk. The

divers later entered the trunk and endeavored to squeeze through the small

oval hatch at its lower end. Here Kelley stuck about halfway through, and it

was then decided to try the doors instead.

On October 25, 1925, the first four pontoons arrived on board the 100-ton

derrick "United States". They were brought direct to the wreck, but about an

hour after arrival the weather changed and it was apparent that the derrick

was in danger. It was immediately started for Newport, where it arrived not

much ahead of a gale which scattered the salvage squadron. It was clearly

evident that derricks could not safely be brought out, and the "United States"

thereafter stayed in harbor where she put the four pontoons overboard and

prepared them for towing out.

Go to section: 1 | 2 | 3 | 4 | 5 | 6 |

Return to: | Contents Page | Index |