----------------------------------------------------------------------- Page 49

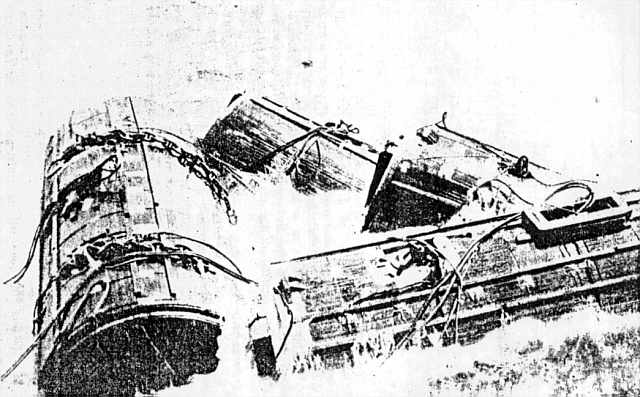

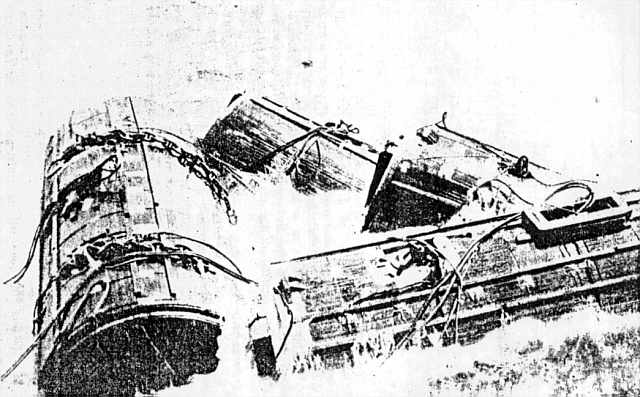

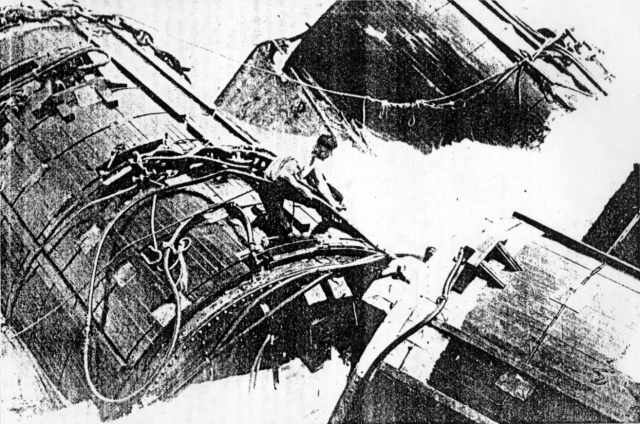

Figure 16: Bow pontoons driven out of alignment by the sea,

June 22, 1926.

----------------------------------------------------------------------- Page 50

This decision was the proper one under the conditions, but carrying it out was

dangerous. All flood and vent valves on the four pontoons at the bow were

closed. The motion of the pontoons was violent and erratic; seas swept over

them steadily.

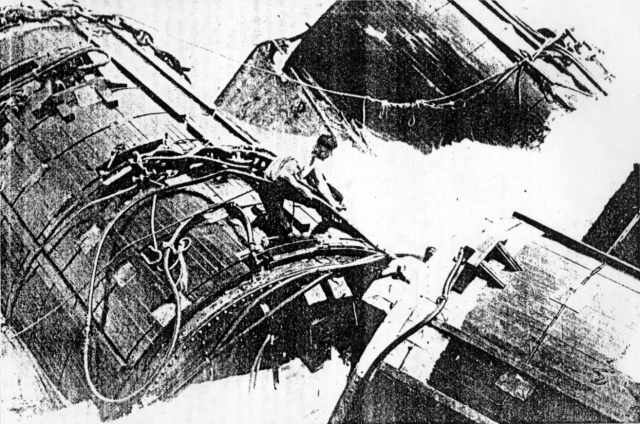

The order to open the valves and sink the pontoons was given to Boatswain

Hawes and the surfboat crew (see figs. 17 and 18); three men, Badders,

Wickwire, and Weaver, volunteered to carry it out. One at a time they boarded

the pontoons and fought the sea; pounded into a state of collapse they were

successively hauled back to the surfboat each with the valves on his pontoon

open; with his men all gone Boatswain Hawes himself leaped aboard the last

pontoon and swung open its valves.

The pontoons flooded quickly and settled evenly; No. 1 port pontoon showed

slightly for about 10 seconds after the others had completely disappeared and

then vanished; the "S-51" sank the rest of the way with no disturbance visible

at the surface. The "Falcon" buoyed off all hoses, let go the moorings at

about 2 p.m., and with all other vessels of the salvage fleet ran for shelter

at Point Judith.

The two pontoons which had gone adrift were soon brought in behind the

breakwater by the "Sagamore" and the "Wandank". In the late afternoon the

broken chains were removed by the "Falcon", and the "Vestal" repair party

immediately started to recondition the pontoons. A 100-ton floating derrick,

the "United States", had a week before been towed from the New York Navy Yard

to Point Judith to be handy for contingencies even though she could not safely

be taken out to sea; a crew for the derrick was mustered from the personnel of

ships present, and with the repair ship "Vestal" and this derrick a miniature

navy yard was at once put in commission, which shortly did remarkable work.

While the events were still fresh, a study was made to determine the causes of

what had happened. It was concluded that the bow pair of pontoons must have

been more buoyant than estimated; this was evidently the case with the No. 3

pair also. In the case of the bow pontoons the leakage after the valves were

closed must have been much less than what the bubbles at the surface

indicated. No means, unfortunately, existed of knowing the buoyancy inside a

pontoon, unless it happened to be completely empty or completely full; other

than in these two conditions its buoyancy could only be estimated with the

flow of air in through a long hose and the leakage of air out through the

battered shell as two highly uncertain factors governing it.

It appeared that sufficient buoyancy had accumulated forward when work ceased

late on June 21 to give a slight positive lifting moment at the bow. Motion,

however, was prevented by the suction effect. The air put in during the

morning was either aft or amidships and could have had but a negligible effect

on the forward lifting moment; actually the air put in the stern pontoons

would tend to reduce the forward moment by shifting the center of buoyancy aft

and would help to hold the bow down.

It is probable that the motion of the sea was sufficient to rock the "S-51" in

her bed on the bottom. Such motion at that depth had been observed previously

by divers in the swaying back and forth of the pontoons afloat over the hull.

On this occasion the lightened ship was rocked sufficiently to break loose the

suction on the bow, which rose with accelerating force as the expanding air

forced water out of the bow pontoons on the way up and increased the

buoyancy.

By the afternoon of the following day, the sea had subsided enough for diving

and the "Falcon" returned for an examination of conditions.

The "S-51" was found with a strong starboard list, about 20 degrees, and with

the bow clear of the bottom back to frame 40; the stern was on the bottom.

There was no evidence either forward or aft of damage to the "S-51" due to the

events of the previous day, except some dents in the bow buoyancy tanks where

the pontoons had rubbed. The midship pair of pontoons

----------------------------------------------------------------------- Page 51

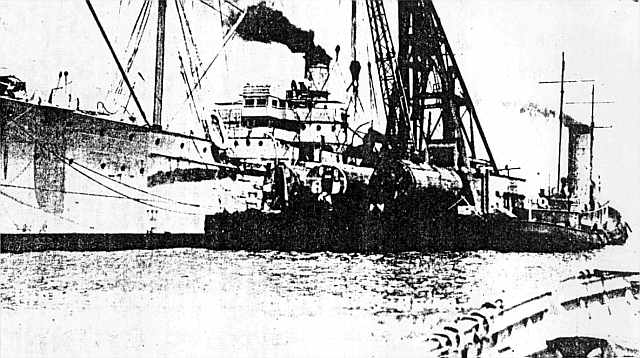

Figure 17: Wickwire boarding bow pontoons, June 22, 1926.

----------------------------------------------------------------------- Page 52

(No. 3 pair) was afloat in proper position abreast the conning tower, but both

the No. 1 and the No. 2 pairs of pontoons were in a huddled group at the bow.

Three of these pontoons were standing vertically on end alongside the

submarine; the fourth one was floating horizontally about 5 feet above the

submarine's deck. All four of these pontoons were battered and out of

position; it was clear they would have to be cast loose and brought up for

repairs.

The bow of the submarine was found about 15 feet to starboard of its former

location, the boat evidently having swung somewhat with the storm.

Except for the work required to remove and replace the four bow pontoons and

to replace the two pontoons carried away at the stern, the condition of the

job did not look worse than two days before. The condition of the divers,

however, was critical. They were much worn from their previous exertions,

especially during the last two weeks, and they were in no condition to

undertake another strenuous diving operation. To some of them the job looked

hopeless and their spirits were at low ebb. It was with some difficulty that

the surface and diving crews were made to see that an immediate continuance of

work was imperative; when convinced that success was possible the divers

turned to again with an enthusiasm and a vigor that far surpassed their

efforts of the preceding month.

The first operation attempted was to run through a pair of reeving lines for

replacing the No. 2 pair of pontoons. The keel here was barely touching the

bottom and it was essential to get the lines under before it settled. One

line was passed through at frame 30 and the divers sawed it back to frame 42,

its designated location. For the second reeving line, this could not be done,

and Eadie had to wash through a new tunnel at frame 50, which he was able to

complete in about one hour, this speed being due to the new nozzle. The first

line through the tunnel was cut in half by the bilge keel and another had to

be run. On the reeving lines, wire lines and then a pair of 2.5-inch chains

were run through; the wires and the chains were laid out on the bottom until

wanted.

The next step was to clear away the pontoons at the bow. The pontoon still

afloat was secured across the submarine by the lashing wires and these had to

be cast loose. One of the wires lay across the deck where it was easily

reached by Chief Torpedoman Kelley and cut with the torch; the other wire ran

about 6 feet clear of the side and was out of reach from the deck; furthermore

it was under a strain from the floating pontoon. To cut this wire, Kelley

lashed the torch to the end of a squilgee handle, reached out toward the wire

with the torch already lighted and the cutting trigger pulled, and speedily

burned the wire in half. Freed of this strain, the pontoon swung across the

deck toward the divers, who started to run; it caught one of them and knocked

him off the boat; the pontoon then rose about 10 feet until it took up on both

chains. Kelley managed to haul his partner back aboard, fortunately not

injured, and both divers came up safely but badly shaken.

Before proceeding further, it was necessary to sink this pontoon, the flood

valves of which had not been touched while it was on the surface, as they were

inaccessible then. The next divers down on the job found this pontoon still

afloat but almost vertical, and reaching the valves was difficult; the next

day this was accomplished and the pontoon sank, still standing on end. This

completed a trying situation, all four of the bow pontoons being vertical

which was their worst position for work.

An attempt was made to capsize the port No. 2 pontoon by attaching a 6-inch

manila line to the high end and hauling on it with the "Falcon"; after some

heaving the line broke but the pontoon stayed as it was.

In view of this failure, it was determined to attempt the release of the

toggle bars holding the chains to the pontoons; even though the diver would

have to work on a vertical surface, Grube, one of the newly trained divers,

went down on this job and hanging by his life line (which was tended from the

top of the pontoon by another diver) managed to remove the locking pins

----------------------------------------------------------------------- Page 53

Figure 18: Wickwire clearing air hose, June 22, 1926.

----------------------------------------------------------------------- Page 54

and haul the 130-pound toggle bars out of the chain links, thus freeing the

chains. When the divers were clear, the air was turned on and this pontoon

soon floated up; the mate pontoon of this pair was then blown clear of water

and came up, bringing the pontoon chains with it. Both pontoons were

dispatched to Point Judith in tow of tugs for repairs.

The bow pair of pontoons took two days to cast loose and bring up, due to the

tangled condition of the chains and the hoses. When finally raised, the port

bow pontoon was found to have several large holes punched in its side; both

bow pontoons were well battered and were sent to Point Judith for overhaul.

The bow towing bridle previously installed was found useless, as it had torn

free of the port bow plane guard through which it passed; Kelley burned the

bridle in half and sent it up. A new towing pennant of chain and wire was

sent down and shackled into the bullnose; this pennant was the one actually

used later for towing. As a preventer, another towline was secured around the

gun mount with a length of 1.5-inch chain and held in position near the bow by

a 1.5-inch chain bridle passing completely around the ship; from this point a

towing wire led forward. Both the above towlines were laid out on the bottom

ahead of the "S-51" and buoyed off.

On the evening of June 30 the divers had completed all work on the towlines

and in clearing away damage; the "S-51" was again ready to attach pontoons.

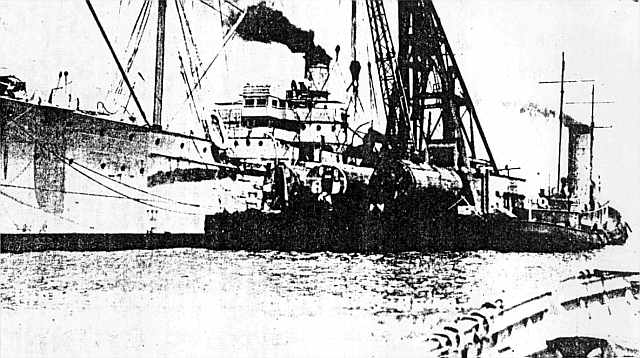

Meanwhile at Point Judith the damaged pontoons had been hauled out of water by

the derrick "United States" and landed on her deck. The derrick was secured

alongside the "Vestal" (fig 19) and the repair forces of the "Vestal" worked

night and day to repair and calk the battered steel cylinders and replace the

missing wood sheathing. New valves and sheathing were hurriedly shipped from

New York.

By the end of June the first pair of pontoons was ready the other two pairs

were well advanced. The presence of the "Vestal" avoided a delay of two weeks

which would have been required to send the pontoons to the nearest industrial

plant for repairs.

On July 1 the "Falcon" was ready to lower pontoons, and the first pair was

towed out from Point Judith. The weather was rather bad for lowering

pontoons, but the lowering operation was successfully carried through without

mishap, the pontoons being lowered and secured to the chains which had some

days before been run through and laid out for the No. 2 pair of pontoons. An

attempt was made to combine the leveling-off operation with the lowering of

the second pontoon of this pair by holding the pontoon over the submarine with

the 12-inch lowering lines while the first pontoon was floated off the bottom

into position. On account of the violent motion of the suspended pontoon, the

divers were unable to stay on the ends of the second pontoon long enough to

open the flood valves, and came up seasick from the motion. As the pontoon

could not be made buoyant without first opening the food valves, nothing could

be done except to sink the first pontoon again and lower the second one to the

bottom, where the 12-inch lowering lines were cast off. The manila lowering

lines were so stretched and reduced in diameter by the strains on this day

that they had to be discarded and a new pair provided for the remaining

pontoons. Fortunately a spare set of 12-inch lines was available on the

"Vestal".

On July 2 a pair of reeving lines was run under the stern of the submarine,

the wires hauled round, and a pair of 2.625-inch chains rove through and

equalized. A pair of pontoons was lowered and secured, but as the weather was

as bad as on the previous day, no effort was made to level them off.

On July 3 the last pair of reeving lines was run under the bow. To keep them

from slipping up the rising forefoot and getting clear, the divers first

secured a piece of 2-inch pipe from the mushroom anchor hawse pipe in the keel

down to the bottom, into which the pipe was driven about 1 foot. The reeving

lines were run through abaft the pipe and followed up with the wires and the

2.625-inch chains; the after chain was passed through the starboard and port

bow plane guards; the forward chain came in way of the anchor well in the

keel.

----------------------------------------------------------------------- Page 55

Figure 19: Damaged pontoons aboard derrick

"United States" at Point Judith.

----------------------------------------------------------------------- Page 56

The port pontoon of this pair was successfully lowered and secured. In

submerging the starboard pontoon of the pair, preparatory to lowering, the

forward lowering line, which was wet, slipped on the bitts while the flood

valves were being closed and the pontoon went down at this end enough to carry

the extension wrench about 4 feet under water, the flood valve being still

open. Badders, who was trying to close the valve, jumped into the water, and

by several dives got the valve nearly closed, when the extension wrench hit

the side of the "Falcon" on a surge and carried away.

As the pontoon could not safely be lowered with a partly open flood valve,

some air was blown into that end of the pontoon to lighten it somewhat; by

that time Eadie was ready in a diving rig and was put overboard in it to close

the valve, which he did about 8 feet under water.

The pontoon was then lowered to its position over the submarine, where it was

held while the diver inserted the toggle bars. The mate pontoon was blown off

the bottom and floated up into position over the submarine. When this was

done, the divers opened the flood valves on the suspended pontoon and it was

blown until it became buoyant, as indicated by loss of strain on the lowering

lines. When this was attained, the lowering lines and wires to chains were

cast off and the bow pair of pontoons was leveled off in final position. The

flood valves were immediately closed to minimize leakage.

This pair of pontoons was the only pair that the salvage party was able to

lower, secure, and level off afloat in one continuous operation. Its success

was due to the moderate weather which prevailed that day, better weather being

needed for leveling than for lowering.

Three pairs of pontoons having been lowered and secured in three successive

days, the morale of the salvage force was considerably bolstered up, and the

men were driving hard again to clean up the job and get away.

On July 4 the "Falcon" rigged for leveling pontoons, with only a moderate

swell. The standard method was used. Commencing with the No. 2 pair of

pontoons, a 1-inch wire was secured to each end of the starboard pontoon.

This was gradually lightened by blowing until the "Falcon" winches were able

to lift it when it was hoisted into position above the submarine. The port

pontoon was then blown until it floated up level alongside the starboard

pontoon (as usual, the port pontoon rose one end first). The starboard

pontoon was then blown until it was buoyant, after which it was cast loose,

and the flood valves closed on both pontoons.

The "Falcon" then shifted position and quickly leveled off the stern pair of

pontoons in the same manner.

One of the divers next went down with a blowing hose and blew out the port

side ballast tanks Nos. 3, 4, and 5 through the open Kingstons. To get at the

starboard tanks, it was necessary to wash the Kingstons clear, as the

submarine had a bad starboard list. This was done and the starboard ballast

tanks Nos. 3, 4, and 5 were blown dry.

The pontoons now being in position, lashing was started. The old lashings on

the No. 3 pair of pontoons were found intact, with no work required. A pair

of wires were measured off and sent down for installation as lashings on the

new No. 2 pair of pontoons. The divers installed the wire lashing on the

after chain, but were unable to install the wire on the forward chain as they

found that the forward end of the port No. 2 pontoon had sunk until it rested

on the bottom; the forward end of the starboard pontoon had correspondingly

gone up. As no appreciable external leakage was visible, it was believed that

the internal bulkhead must have leaked, allowing considerable water to flow to

the forward end of the port pontoon and thus causing that end to sink. On

account of the lateness of the hour, nothing could be done that night.

July 5 dawned with passable weather, a choppy sea, and a moderate swell. As

the weather prospects for the next day were poor, it was decided to blow the

submarine that day and get out before the next storm; consequently, diving

commenced unusually early.

----------------------------------------------------------------------- Page 57

The first step was to level off the No. 2 pair of pontoons again. To do this,

a pair of 1-inch wires was secured to the starboard pontoon, the forward end

of which was floating high, and a vent hose to the surface was also connected

to the vent valve at the high end. The diver also opened all flood valves on

both port and starboard pontoons of the pair. The forward end of the

starboard pontoon was then vented and the forward end of the port pontoon was

blown. The wire line to the forward end of the starboard pontoon soon

developed a strain; it was lowered away gently until the pontoon was level;

meanwhile the forward end of the port pontoon floated up until that pontoon

also was level. Both pontoons were then given additional air all around to

insure buoyancy and the leveling wires were cast off. The remaining lashing

wire was then secured across the deck of the submarine to the forward chain,

and all essential lashings were complete.

Eiben went down forward to secure the open end of a diver's air line to the

stem, to act as a telltale to indicate the rise of the bow. Eiben also opened

the flood valves on the bow pair of pontoons.

Wickwire went down aft to secure a similar telltale to the stern and opened

the flood valves on the stern pair of pontoons. Knowing that he was making

the last dive on the job, on behalf of all the divers Wickwire kissed the

"S-51" good-by and (demonstrating the firm faith of the divers in their work)

promised to meet her next in the dry-dock at New York. Wickwire came up

shortly before noon.

Certain forward tanks, which on June 21 were dry, were on this occasion left

flooded. The No. 2 bow buoyancy tank was considered lost, as it was evident

that the deck forming its tank top was dented enough to make it nonwater-tight

and the capacity of the tank did not warrant repairs. The forward trimming

tank and the water round torpedoes tank had vented themselves down practically

to atmospheric pressure while the bow was at the surface. On sinking again,

these tanks reflooded nearly full under the bottom pressure. Had time

permitted they would have been blown down again, but the weather forecasts

were such for the following day that it was considered unsafe to risk further

work which would run the job over until July 6, when a promised storm would

put the expedition in the same position as two weeks before. Work on the

forward tanks was abandoned, but with regret.

Another consideration causing some anxiety was the fact that about 150 tons of

buoyancy in the six forward pontoons was going to be unavailable for lifting

the bow while the stern was up. (Pl. 5.) This resulted from the fact that

when the stern rose to the surface, the six pontoons forward would assume the

angle of the boat, about 25 degrees. Under such an angle, the after half of

each pontoon could be blown down only until the air reached the flood valve,

when it would escape, leaving a considerable wedge of water, amounting to 25

tons per pontoon, which could not be blown out until the bow reached the

surface and the pontoons leveled off. The reoccurrence of such a condition

can be prevented in future operations by fitting a sluice valve in the center

bulkhead with an outside control rod. By leaving the flood valve to the end

of the pontoon which will rise first closed and the sluice valve open (this to

be done after the pontoon has been leveled and lashed) all the water in the

high end can be blown out through the low end flood valve, thus obtaining the

complete buoyancy of the pontoon, for lifting while on the bottom.

It had been the intention originally to make sure of this buoyancy by blowing

the after halves of all six forward pontoons dry before lifting the stern; the

forward halves could be blown completely dry in any position. Plate 5

illustrates this. However, with the experience of June 22, in the background,

this intention had to be abandoned; no chances could now be taken of letting

the bow rise first, and it was considered imperative that the stern be up

before any additional buoyancy (beyond what was necessary to float them) be

given the six forward pontoons.

Confirming the soundness of this position, the last two divers up reported

that the "S-51", which up to the evening before had had a list to starboard of

at least 20 degrees was that morning

----------------------------------------------------------------------- Page 58

nearly upright, with a list of not over 5 degrees to starboard. It was clear

that the submarine was again moving, with slight or no suction holding her.

The condition on the morning of July 5 of the compartments and tanks which

were available on June 22, with the buoyancies which were expected in them

when the ship rose, was as follows:

-------------------------------------------------------------------------------

| | Buoyancy |

Compartment | Condition at | at noon, | Expected

| noon, July 5 | July 5 | Buoyancy

--------------------------------------+-------------------+----------+---------

No. 2 bow buoyancy tank ..............| Flooded ..........| 0 | 0

Forward trim tank ....................| .. do ............| 2 | 2

Water round torpedo tank .............| .. do ............| 1 | 1

Port ballast tanks 3, 4, 5 ...........| Dry ..............| 50 | 50

Starboard ballast tanks 3, 4, 5 ......| .. do ............| 50 | 50

C.O.C. ...............................| Flooded ..........| 0 | 60

Engine room ..........................| .. do ............| 0 | 96

Motor room ...........................| Three-fourths dry | 100 | 137

Tiller room ..........................| .. do ............| 12 | 12

After group oil tanks ................| .. do ............| 25 | 33

| | -------- | --------

Total compartments ................| ..................| 240 | 441

===============================================================================

| | Buoyancy |

Pontoons | Condition at | at noon, | Expected

| noon, July 5 | July 5 | Buoyancy

--------------------------------------+-------------------+----------+---------

No. 1 pair (bow) .....................| Just buoyant .....| 20 | 110

No. 2 pair ...........................| .. do ............| 20 | 110

No. 3 pair ...........................| Partly buoyant ...| 80 | 110

No. 4 pair (stern) ...................| Just buoyant .....| 20 | 160

| | -------- | --------

Total pontoons ....................| ..................| 140 | 490

Grand total for lifting ..............| ..................| 380 | 931

| | ======== | ========

Reserve buoyancy in Nos. 1, 2, 3 pairs| | |

of pontoons (regained at surface) .| ..................| .........| 150

Forward group oil tanks | | |

(to be blown at surface) ..........| ..................| .........| 43

| | | --------

Additional attainable buoyancy | | |

at surface .....................| ..................| .........| 193

Total buoyancy at surface for | | |

towing operations ..............| ..................| .........| 1,124

-------------------------------------------------------------------------------

It will be noted that the margin for lifting the bow from the bottom was not

great, but it seemed adequate. Furthermore, in a pinch there was always

available the forward group of oil tanks with a buoyancy of about 43 tons,

which could be blown while on the bottom, although at the risk of bulging or

bursting the tank top when on the surface. However, even if these tanks

ruptured under such use for lifting, it could only happen at the surface and

by then the lost buoyancy in the forward pontoons would again be available to

counteract the loss of the forward fuel-oil tanks.

On the above calculations it was deemed best to proceed with the raising and

risk no delay merely to obtain added buoyancy forward.

When the last diver had left the bottom the "Falcon" hauled clear, with the

submarine about 150 feet away on the port beam and parallel to the "Falcon".

The mooring buoys ahead and astern were dragged clear to afford an approach

for the "Sagamore", which steamed in ahead and picked up both the buoyed-off

bow towing lines to the submarine; and for the "Iuka", which came in astern

and similarly picked up the stern towline to the "S-51".

On the "Falcon's" starboard side the mooring buoy there was dragged clear and

the "S-50" moved in close aboard, where she anchored and a 2.5-inch fire hose

was run to her to carry compressed air to the "Falcon's" manifold.

On the "Falcon's" forward manifold, with 12 valves, were secured the blowing

hoses to the compartments (4 hoses) and to the No. 1 and No. 4 pairs of

pontoons (8 hoses). To the manifold on the port side, with 10 valves, were

secured the hoses from the No. 2 and No. 3 pairs of pontoons (8 hoses) and the

2 telltale hoses leading to the bow and stern of the submarine. Below the

manifold valve to each hose was secured a pressure gauge, so that the

----------------------------------------------------------------------- Page 59

pressure in any compartment or pontoon could be determined by shutting the

line off momentarily from the manifold and permitting the pressure to balance

in the hose with that in the compartment.

At 12.17 p.m. Wickwire was hauled out of the water and the compressed air was

turned on both motor and engine rooms. With both low-pressure compressors and

the high-pressure compressor on the "Falcon" going full speed, and all the air

that the "S-50" was able to supply through the fire hose, it was possible to

maintain a pressure in the manifolds of 90 pounds.

At 1.17 p.m. after blowing an hour, a stream of air started discharging at the

surface over the engine-room hatch; blowing was kept up a few minutes longer

to make sure both motor and engine rooms were dry.

At 1.25 p.m. air was turned on the C.O.C. Within a minute air started to

discharge at the surface over the vicinity of the conning tower. This was a

severe shock, as it could only indicate that the C.O.C. had previously been

nearly dry, or that the air was escaping from the C.O.C. as fast as it

entered, or that the blowing hose to the C.O.C. had carried away somewhere

near the submarine. It being well known that the C.O.C. was practically

flooded up to that time, it was deduced that no buoyancy was being gained or

was going to be gained in the C.O.C., for all the air was escaping either

through a broken hose or through possible damage over the conning tower.

No examination could be made, as the "Falcon" was not in diving position over

the boat; to get her there would take several valuable hours from the

afternoon; besides it was dangerous to bring the "Falcon" over the already

buoyant stern of the "S-51", not to mention the danger the diver ran of being

caught on a rising boat.

Delay was undesirable in view of weather conditions.

A check of the situation showed a loss due to the C.O.C. of 60 tons; this loss

was about equally divided between bow and stern due to the central position of

the C.O.C. The stern could easily stand the loss; the bow could hardly afford

it, but as even the bow still figured a small margin, it was decided to

proceed. The use of the forward group of fuel-oil tanks with its 43 tons of

buoyancy now began to appear necessary in spite of the possible danger of

damaging the tank tops.

The C.O.C. was thus seen to be lost, but as it was isolated from the engine

room abaft it, the latter compartment was in no way affected and there was

then justified all the extra labor which had been expended by the divers in

making each compartment a separate water-tight unit.

At 1.55 p.m. air was turned on both ends of the stern pair of pontoons and on

the after ends only of the forward (No. 1) pair of pontoons.

At the same time, the pressure in both engine and motor rooms, which was equal

to the bottom pressure, about 57 pounds, was reduced by opening their blowing

hose vent valves on deck and allowing them to vent to the atmosphere until

the pressure had dropped in them to about 35 pounds. The water could not

reenter due to the nonreturn valve in the spill pipe in the engine-room

salvage hatch. The reason for this reduction in internal pressure before

raising the stern was that no salvage hatch had been fitted to the motor

room. The regular hatch to that compartment was left in place and held down

from the outside by an additional bolted strong back, but it was not desired

to expose this hatch and strong back to any more internal pressure during the

rise than was necessary, consequently the venting down before the rise.

At 2.06 p.m., after blowing the stern pontoons for only 11 minutes, a large

mass of bubbles appeared at the stern; shortly after the stern pontoons broke

through the surface, riding easily with over half their volume exposed. They

were probably not over half buoyant when the stern started to rise. (See

figs. 20 and 21.)

45129-27--5

Go to section: 1 | 2 | 3

| 4 | 5 | 6

|

Return to: | Contents Page | Index |